cartridge heaters, also known as single-ended heating rods, or electric heating elements, are a type of electric heating component used in various industrial equipment for heating applications.

They are widely employed in machinery such as plastic packaging machines, soldering equipment, thermal stamping machines, pharmaceutical machinery, and 3D printing devices.

These cartridge heaters not only withstand the rated voltage during long-term operation but also handle transient over voltages that may occur during the operation, which often exceed the normal operating voltage. It is crucial that the insulation of the cartridge heater meet the required withstand voltage standards to ensure safe and reliable operation.

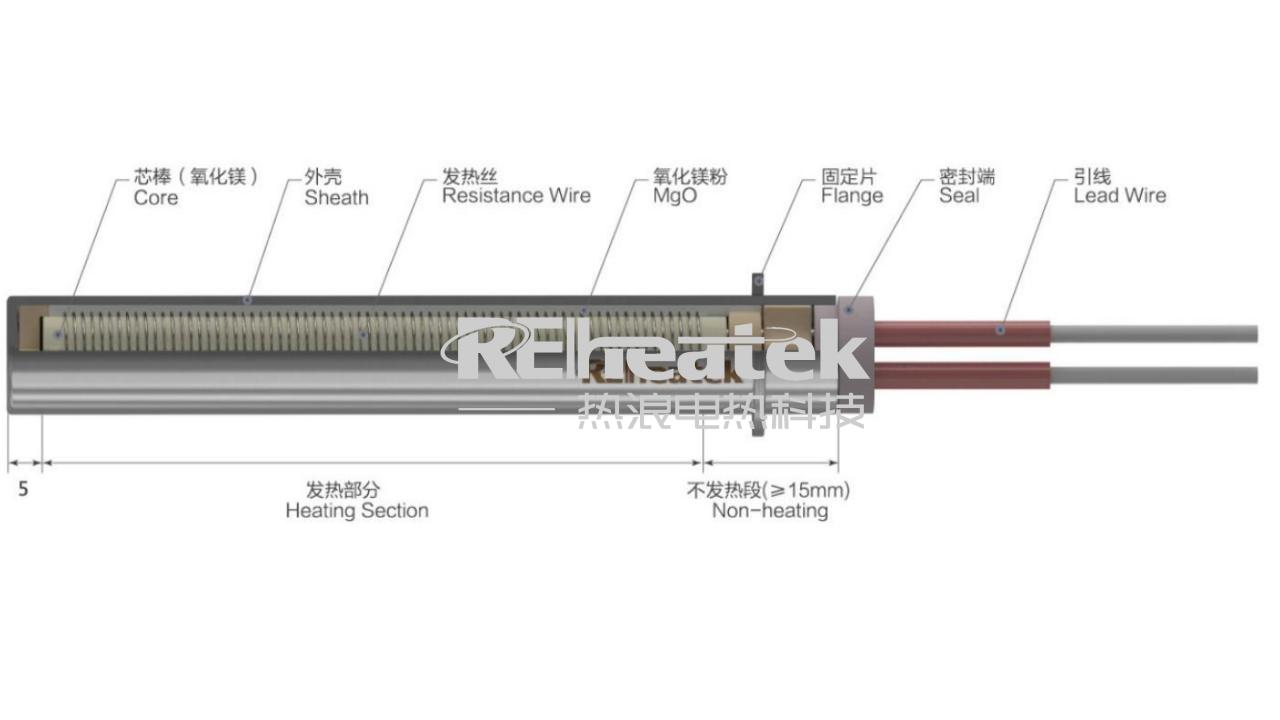

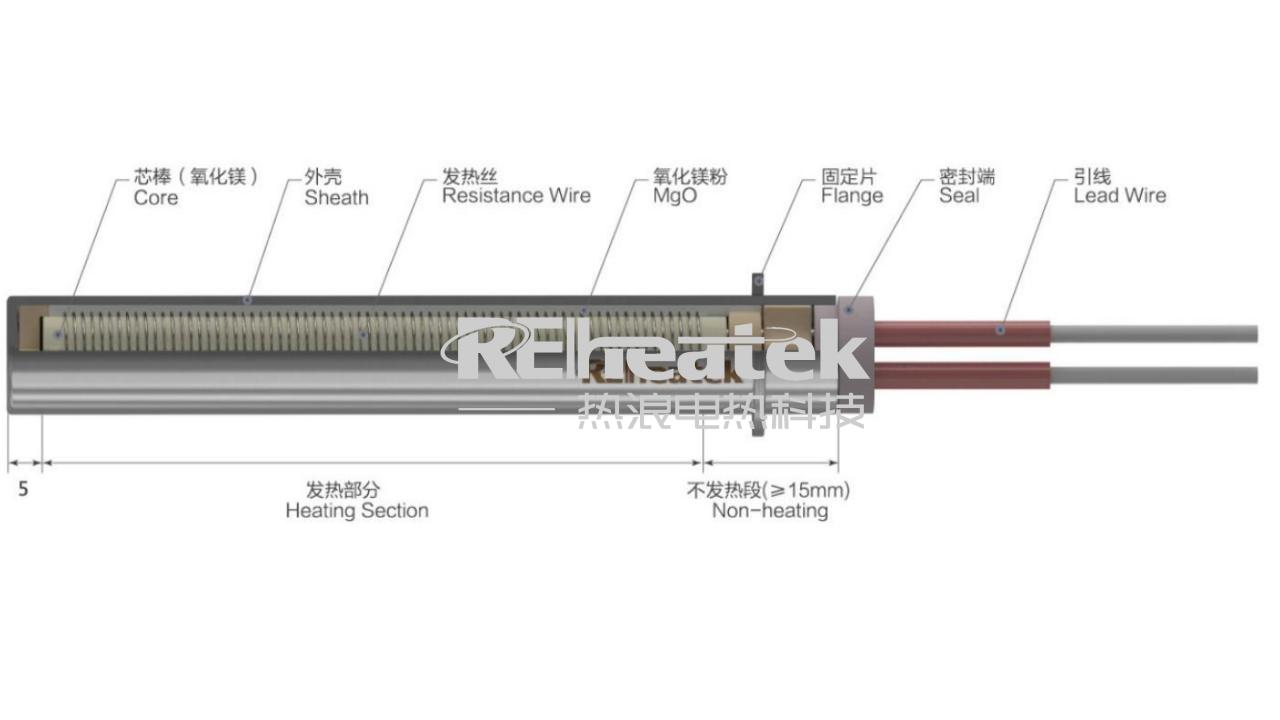

Let's take a closer look at the structure of a single-ended cartridge heater. It consists of a stainless steel tube as the sheath, inside which the heating core is tightly wound. REheatek always use a nickel-chromium resistant alloy wire (Ni80Cr20) to wrapped around a magnesium oxide core. This construction provides excellent electrical insulation properties and enhances the overall thermal conductivity of the cartridge heater. At REheatek, we have accumulated over a decade of experience in manufacturing high-quality cartridge heaters. We always focus on improving the insulation withstand voltage performance to ensure the safety and reliability of our products.

During the manufacturing process of cartridge heating elements, there is a crucial step called "shrinking."

After the heating core is installed inside the stainless steel tube, we will fill in high purity and high temperature MgO between heating core and sheath. Prior to shrinking, there will be gaps between the magnesium oxide particles, which will affect the insulation and thermal conductivity of the heater. With the shrinking machines, we compress the magnesium oxide powder, increasing its density and minimizing any electrical gaps within the cartridge heater. This process significantly enhances the insulation voltage resistance and improves the thermal performance.

About REheatek:

REheatek is a manufacturer with over a decade of experience in the development and manufacturing of electric heating products, we prioritize the highest quality standards in our production. Customer satisfaction is at the core of our business, and we strive to maintain open and effective communication throughout the entire project from design and manufacturing to quality testing and delivery. Additionally, our dedicated after-sales service ensures that your needs are met even after the purchase.

If you have any inquiries or require further information, please do not hesitate to contact us. We are here to provide you with the knowledge and assistance your need for custom cartridge heaters.

E: Joannali@reheatek.com

M: +86 189 1409 1124 (Whatsapp)