Extending the lifespan of a cartridge heater requires proper installation, correct operating conditions, and regular preventive measures. Beyond unexpected failures, factors such as heat accumulation, moisture contamination, and improper wattage selection can significantly shorten a heater's service life.

This guide highlights practical, proven steps to help you maximize cartridge heater durability and avoid common failure causes.

1. Prevent Contamination

Contamination is one of the leading factors that cause cartridge heaters to fail prematurely. During installation, a release agent is often used to assist with heater removal in the future. It is important to ensure the release agent has fully dried before powering the heater.

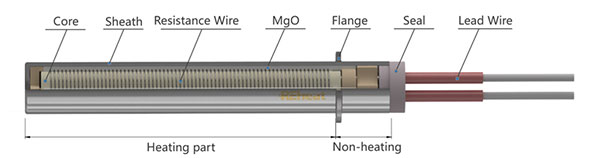

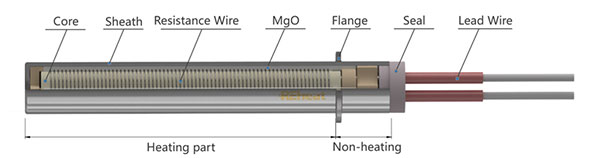

If moisture or fluid enters the heater's protective sheath, the internal resistance wire may become soaked or carbonized at high temperatures—resulting in short-circuits and early failure.

Key tips:

Allow all release agents to dry completely before installation

Keep the heater and installation area free of oil, moisture, and foreign particles

Follow the manufacturer’s installation instructions closely

2. Avoid Overheating

Overheating occurs most commonly when the cartridge heater is installed loosely or unevenly inside the bore. Poor heat transfer causes the heater to accumulate heat internally before it can transfer it to the target object, leading to excessive temperatures.

To maintain optimal performance and prevent overheating:

Install the heater straight and snug to ensure efficient heat transfer

Select the lowest acceptable voltage and appropriate watt density for your application

Avoid using heaters with higher wattage than necessary, as this causes frequent on/off cycling and reduces heater life

3. Unwarranted Cycling

Temperature cycling from 150°F to 1,400°F (66°C to 760°C) is often used to evaluate heater lifespan. However, excessive or unnecessary cycling can reduce durability due to repeated oxidation of the resistance wire.

When temperatures rise, an oxide layer forms naturally on the wire and protects it. But when the heater cools too rapidly, this oxide layer can crack, exposing the wire to further oxidation and accelerating failure.

Best practices:

Maintain a stable operating temperature whenever possible

Avoid frequent power cycling

Use accurate temperature controllers to minimize fluctuations

Need a Reliable Cartridge Heater?

If you're looking for a high-quality cartridge heater along with updated installation guidelines, feel free to contact us for tailored solutions that ensure long service life and stable performance.