Reheatek cartridge heater uses high quality Ni80Cr20 alloy as resistance wire, high purity (99.5%) MgO as insulation, and stainless steel as sheath.

It provides concentrated heat in a limited space, small size but heat up quickly and precisely. A temperature sensor could be built-in to realize real-time temperature feedback and control.

Applications (Mainly):

Metal Blocks - inserted into drilled hole of metal blocks (plates, dies, molds).

Industries:

Plastic processing,Packaging, Medical equipments (Ventilator), Hot bending equipment, 3D printer equipment, Extrusion, Ignition equipment

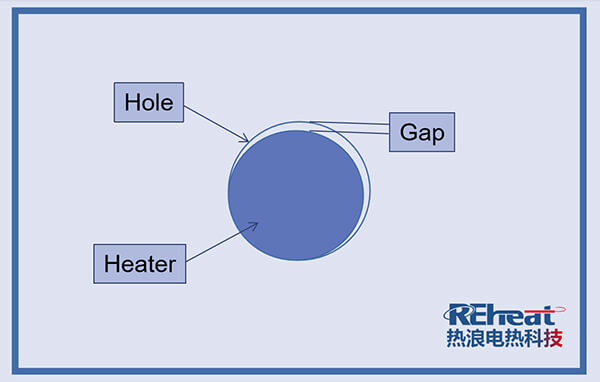

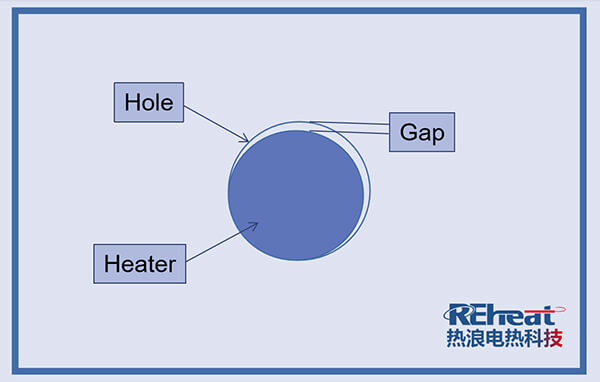

Cartridge heaters are normally used for heating metal parts by insertion into drilled holes. For easy installation, the heaters are made slightly undersize relative to their nominal diameter.The gap between the heater and the hole is important when it's at high watt densities. If the gap is too large, the heat transfer is not good. While the gap is too small, it will be difficult to install and replace the heater.

1.Determine the Gap

The gap is the difference between the minimum diameter of the heater and the maximum diameter of the hole.

For example: required a 10mm cartridge heater (cartridge heater nominal diameter, drill size), actural diameter is 9.93±0.03mm. Drill size is ±0.02mm, maximum gap is 0.12mm.

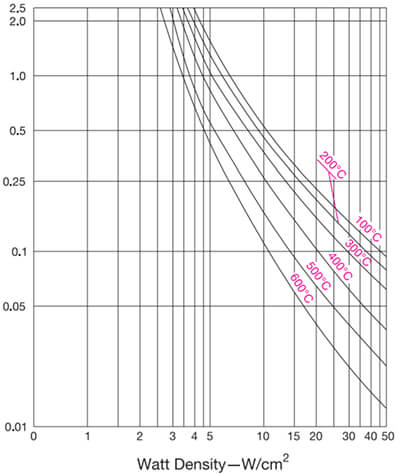

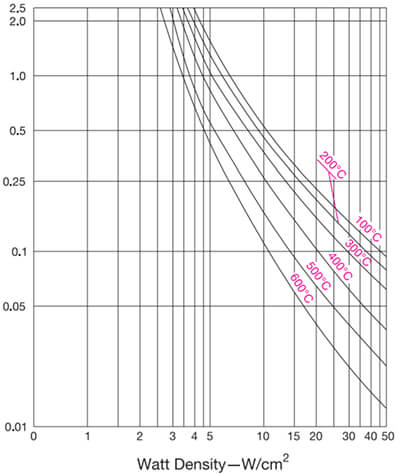

2.Determine the Watt Density

Watt density is the heat flow rate or surface loading. It is the number of watts per square inch of heated surface area.

When maximum is 0.12mm, recommanded maximum watt density is 25W/cm².

Below chart - Recommended watt density (maximum allowance) for heating metal blocks.

3.Power=Watt density(W/cm²)*Heat section(cm)*Norminal heater dia*3.1416

For example, required length 200mm, heat section is 180mm, max. watt density 25W/cm² (as above mentioned)

Power=25*18*1*3.1416=1413W

The above is for reference only, selection of a cartridge heater should take applications into account. The higher the watt density, the shorter the service life. We recommend to consider the following when higher power is requested:

1. Increase the diameter and length of the heater

2. Use more heaters with lower watt density, and extend the heating time

Reheater is a professional cartridge heater manufacturer. Our company has long been committed to the research and development, production, testing and innovation of electric heating elements. Products in the industry has won the praise of our customers. If you have any questions about electric heating, please come for consultation.