Cartridge heaters are one of the most reliable and longest-lasting heating elements currently available. Why do they fail sometimes? In most cases, this is because you have not installed or maintained it properly.

In order to maximize the life of the cartridge heater, there are things you should and should not do. As experts in this field, we think we have some understanding of the subject. Here, we provide some tips on how to take care of your products and prevent unnecessary failures and failures in the future.

Three tips to maximize the life of the cartridge heater

1. Avoid pollution

In order to maximize the use of cartridge heaters, the leads must be protected from potential contaminants. This includes liquids and gases, such as oils, sprays, lubricants, etc. If any of these substances enter the heating element, it may cause a short circuit and eventually cause a malfunction.

It’s also worth noting that every time your cartridge heater expands and contracts, it draws in air from the surrounding environment. Any moisture or impurities in the air will negatively affect the function of the heater. Therefore, it is important to purchase heaters with proper seals.

2. Make sure the heating element fits tightly

The cartridge heater is incorrectly sized and will usually fail prematurely.

The component should be close to the mold. Otherwise, the heat will not be effectively transferred, and the heater will start to operate at a higher temperature than the required temperature. Over time, this overheating can adversely affect the equipment and shorten the life of the heater.

As a general rule of thumb-in order to efficiently dissipate heat as quickly as possible, the diameter of the mold should be no more than 0.1mm larger than the diameter of the heater.

3. Prevent excessive cycling

If the wattage of the cartridge heating element is higher than the required power, it will turn on and off at a rapid rate (for example, every 30-60 seconds) to maintain the desired temperature. This is called excessive temperature cycling. It quickly oxidizes the resistance wire and often causes heater failure.

In order to avoid excessive circulation, it is worth studying. Before purchasing a heater, always establish a minimum power to meet your application requirements.

Need help choosing the correct cartridge heater?

Cartridge heaters are sturdy and durable equipment. If they fail prematurely (nine in ten), it is because the wrong size or power has been selected. But this is where we can help.

Our expert team at Reheatek has unparalleled knowledge and experience in this field. And, if you need help to choose the cartridge heater that suits your needs, we will always be happy to help you.

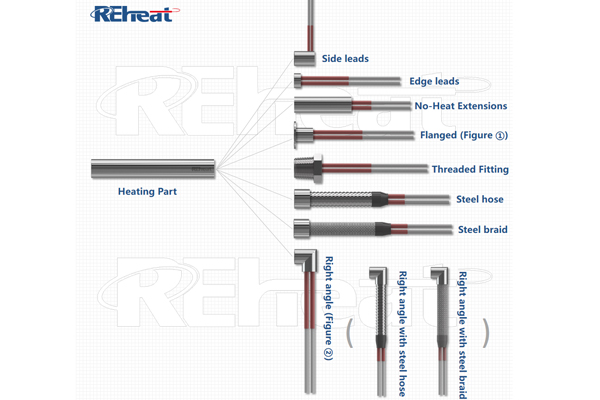

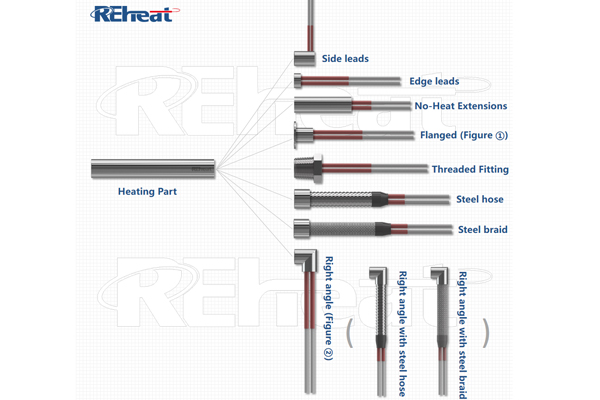

We have a variety of cartridge heating elements in imperial and metric sizes, and can provide tailor-made recommendations and guidance on the best choice for your application. In fact, we even provide custom cartridge heater service. According to our requirements, we can design and create new ink cartridge heaters to meet your exact specifications.

So, why not contact today? Before you click "add to shopping basket", please call us at +86-189-1409-1124 or send an email to vincentpeng@reheatek.com to avoid any unnecessary problems with new products.