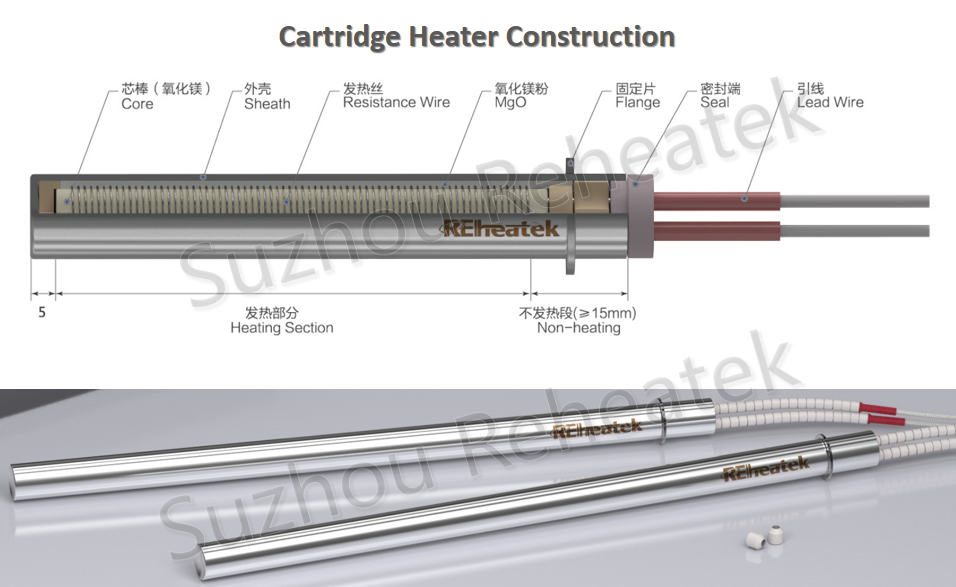

Cartridge heaters (Also called mold heaters, heating elements, industrial heaters, etc.) are made small size,, with advantages of fast heating and convenient assembly, are widely used to heat metals such as mould or platen. Some typical applications such as plastics industry, packaging industry, semiconductor industry etc.

In the process of communicating with customers, we found that many end users do not understand how to use cartridge heaters correctly, the problem of improper use is very common. Improper use often leads to various problems, such as short service life, heater burning out, poor heating performance, wire broken, or even safety problems.

It's important to know how to use the heating element correctly, it helps to ensure the safe operation and prolong the service life.

The following precautions need special attention.

1. Prevent dry heating. The exposure of the heating section will cause the temperature to rise abnormally, resulting in risks such as burning out, disconnection, and even fire.

2. Keep tighter fit. The drilled mold hole must match the outside diameter of the heater. Recommended fit is within 0.1mm.

3. Dry working environment. Make sure that the environment around the wire and the outlet is dry, otherwise it may cause leakage or short circuit.

4. Keep drilled hole and heater surface clean. Before operation, it is necessary to remove foreign matter such as engine oil in the mold hole, otherwise it will cause abnormal heating due to carbonization.

5. Connect to rated power (voltage). Do not use a power supply higher than the rated voltage, otherwise it may cause excessive power and damage the heater.

In addition to the above matters, improper heater design is also a main reason of heater failure.

Suzhou Reheatek Electrical Technology Co., Ltd is a professional cartridge heater manufacturer with 15 years experience. We always take the application details into consideration when communicate with customers to ensure a suitable heater solution.

Please contact us to customize if you need to customize high quality cartridge heating elements.

Contact us at: Joannali@reheatek.com