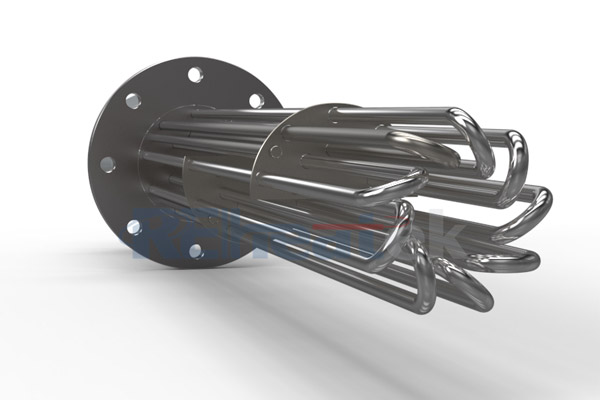

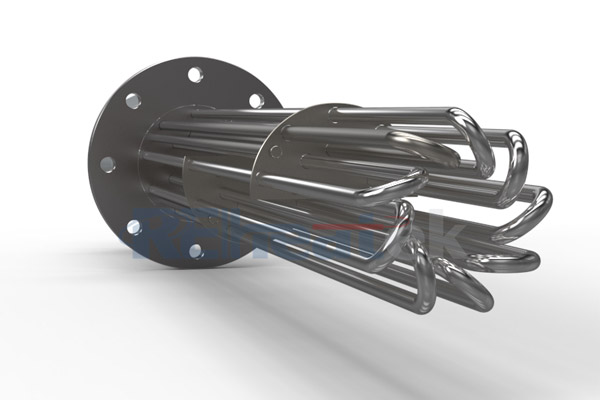

Flange heaters are used majorly for heating gases and liquids such as oil, water, and corrosive solutions. The Flange possesses a tubular element that is bent or a hairpin.

If you need a flange heater for your industrial heating processes, it is advised you purchase from reliable and dependable manufacturers of the best quality extension heaters.

The manufacturing process is by brazing or soldering of the components on a flange, the flange that is ideally suitable for heating in industrial processes are made of steel.

On the other hand, other materials can also be used such as stainless steel, and copper. In this article, we will be talking about the flange heater.

Flange Immersion Heaters

The flange immersion heaters have different covers and flange materials, different energy, power ratings, temperature ranges, and operating systems.

For electrical connections, the heater consists of various types of box terminal. Each terminal identifies its fitness to various situations which can be a wet surrounding.

For temperature control, a sensing bulb is placed in a heating element bundle to help control temperature.

The installation of the flange heater is on a chamber or a container wall with the aid of a companion flange.

Application of Flange Heaters

Primarily, the flange heaters are used particularly in process heating mainly for heating gases and liquids that are in storage tanks, food processing equipment, containers for rinsing, and cleaning. The most efficient method of heating is the direct immersion method.

Selection Of Flange Heaters

1. The choice of flange heater

Choose the most appropriate heater that will be determined by the size and materials, kilowatt ratings, terminal enclosure, sheath materials an number of elements of the flange heater.

2. Evaluate the requirements

The requirement for a flange heater such as heat, voltage, operating environment which may include the fluid used should be evaluated.

3. Knowledge

The engineer who is to install the heater will also need to apply his understanding and insight when it comes to the selection and installation of heaters.

Temperature Checking and Control

Temperature checking and control for flange heaters is delivered through either one of electronic or mechanical devices.

When it comes to controlling temperature with a mechanical device, the heater housing contains a thermostat that functions as an on-off to control the temperature.

The thermostat is installed directly from the factory. While the thermowell comprises a detecting bulb that is proficient in transmitting the temperature readings to a numerical temperature regulator that keeps the temperature at a chosen setting.

Additional a thermocouple is sited in the thermowell this is meant for an electronic-based mechanism of temperature control. The thermocouple is also factory fitted and it is linked to the temperature control.

Protection From Over-Temperature:

There are thermocouples in the flange heaters to help switch off the heater when the temperature gets above the fixed value.

It is mounted on the heating element cover this gives sheath limit protection and controls temperature.

When considering to buy flange heaters, teaming with a reputable manufacturer is the best option for the best deal.

Contact us for a high-performance flange heater

We provide the best heating solution for any industrial or domestic heating you may need with our flange heater and other types of heaters.

In case you need a trusted supplier to work with, kindly click here to contact us for any of our high-quality products.