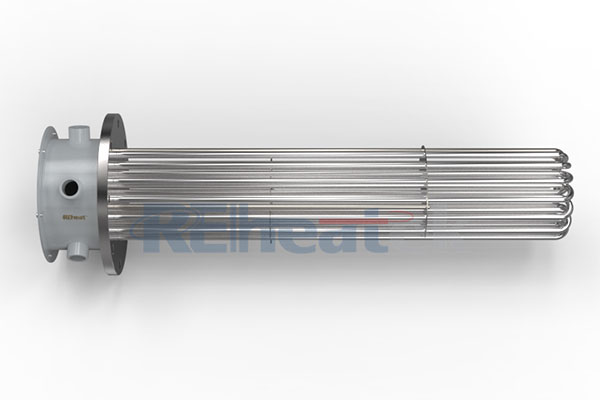

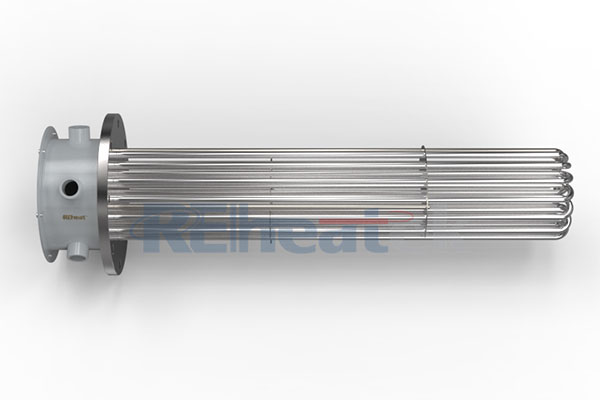

A flange heater is made up of hairpins that are bent in a tabular element which are attached to a flange, through a wired box that is used for electrical linkages.

It is usually installed by bolting the flange heater to a corresponding flange. More so for an effective outcome, you are advised to ensure that you install the heaters using a direct technique that can monitor and control the heat thereby helping to conserve the energy.

There are several manufacturers of flange heaters, however, buying from reliable and trustworthy suppliers will guarantee you a perfect quality product.

This article will discuss the various application of the flange heater. Follow thru for a clearer view.

Application Of Flange Heater

The flange heaters are used in the heating and processing industries to heat gases and various liquids such as lubricants, heat transfer fluid, eroding solutions, and water.

The flange heaters are designed in a way that makes it possible for their usage in water tanks and pressurized vessels.

The major aim of why the flange heaters are designed in a particular way is to optimize the heater so that there will be an increase in the life of an application and also minimize the general product application and life series price.

The heater is easily installed in applications and sustained so that it can continue to provide heat in various applications like

1. Corrosive solution heating,

2. Parts cleaning solution,

3. Process elements reactors,

4. Hydraulic heat and transfer oils, lube oil and fuel oil heating,

5. Rinse tank heating, Boiler, and water heating,

6. Freeze protection and wintering.

These Flange heaters do not exist in the same style, shapes, and pattern and so most manufacturers aim at making simply effective heaters that will help resolve your numerous industrial requirements.

Parameters that affect the performance of flange heaters

The choice of your flange heater can be made by picking the desired sheath material and a suitable optimal fitting technique, as well as elements that are used to manufacture based on the flanges watts thickness.

Depending on what the heaters are supposed to do, they can be customized to standard for specific purposes, either for use in the army, police, and, navy or for industrial targets.

It is believed that you should expect a heating solution fix up to suit your requests for a flanged heater.

On the other hand, several parameters have an impact on the application of your heater, these parameters include,

1. The heater sheath material corrosion-resistant properties

2. The availability of contaminants in the medium

3. The Viscosity of a heated medium, corrosive properties, and the specific heat density

4. The Watts density of the heating element

5. The Maximum temperature that is recommended

Cooperate with us for high-quality Flange Heaters

If you desire to have hi-tech electrical heating and control systems for various applications, we offer a wide variety of products for your heating needs.

Kindly contact us for further information about our range of high-quality heating products.