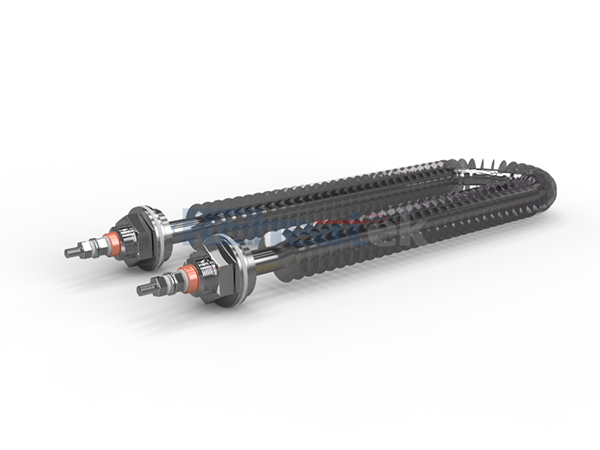

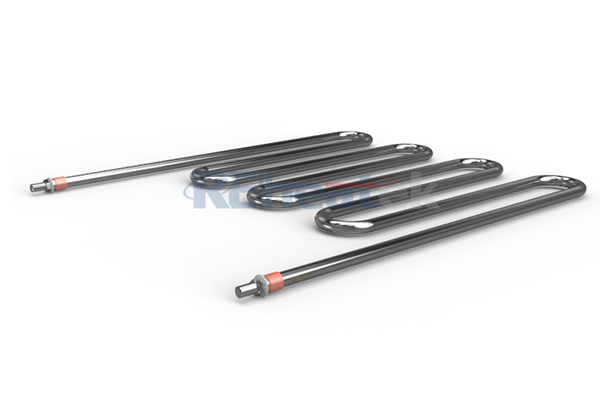

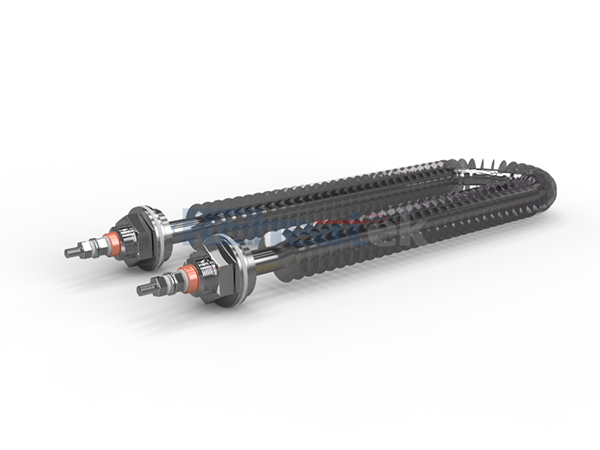

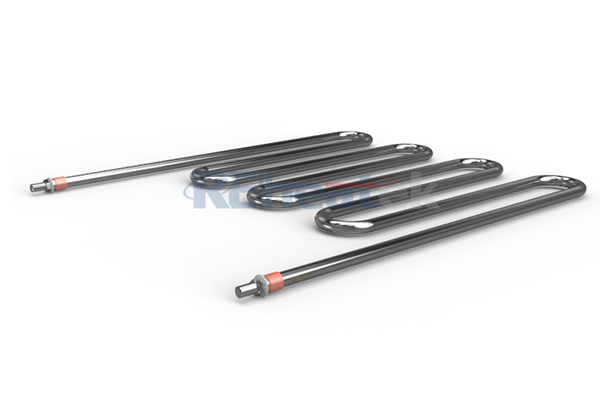

Taking a look across a good range of manufacturing, the use of a tubular heater is inevitable during a myriad of various process heating applications.

Since they can be designed into nearly any shape or size, they are suitable to be used in virtually any situation that will be needing reliable, and economical heating.

This article will give you a quick rundown on what you are likely to realize about these pieces of commercial equipment known as the tubular heater.

How do They Work

These Tubular heaters work basically on either of the three principles of heating which are, convection, conduction, or radiation. It fluctuates steadily within watt thickness, shape, size, and sheath without regarding the actual construction.

Its fabrication is within a restricted region. However, the ensuing hotness is directly emitted into the fabric, linked through an appropriate liquid, or linked through a forced-air system.

Tubular Heaters Installations And their Uses

In Open Air

Tubular heating elements for uses in drying and oven cabinets are compacted rugged heating sources.

The way they are formed are appropriate around other oven workings and effort overhangs, thereby, accumulating heat at a few point.

In Stirring Air

In the Compression fittings, during a duct or air heating chamber, the factory fixed fittings, or supports will support a tubular element.

In Liquids

The listed tubular heaters can also be fixed through the sidewall of a chamber with firm fixtures or by fittings mounted by the factory directly.

Transfer of Heat to Metallic Portions

The existing lengths, diameters, watt densities, ratings, sectional, and extreme temperatures afford the answer for a specified job.

Absorption in liquefied heating

Solutions of water can largely be heated up to any sought after temperature. But if the liquid is struggling, the temperatures ought not to surpass the highest covering temperature of the component.

For Oil reheating

The steel covering components are regularly used in heat transfer oils, heating oils, and other liquids that are not destructive to steel cover.

Gas and air heating system

You are advised to use watt thicknesses that are friendly with the temperatures of work environment. Heaters that are fixed horizontally will be sustained to escape flopping at high heat.

Suitable spacing given to supports will differ with the temperature used, the diameter, of the element, and casing substances. It is generally suitable to use a 12 to 18" space for supports in the tubular heating processes

Where the flow of air over an element permits the use of upper watt densities, confirm if the airflow is uniformly distributed. The permit about 1/8" each base of the length of the element for extension and contraction of elements.

Clamp-On Heating

Use the watt thicknesses that are friendly with work environment temperatures. Heaters ought to be fastened tightly permanently to heat transmission but they should be permitted to increase as they are heated up.

Heaters fastened too firmly will bend far away from the excited surface and this will ends up giving poor heating effectiveness and a possibility of heater failure.

Partner with us for high performance tubular heaters

We are manufacturers of Tubular heaters, contact our office, we have various sizes and shapes of tubular heaters for sale we will be glad to assist you in the selection of our products.