Cartridge heaters play an essential role in industrial manufacturing. Despite their compact size, they can deliver high power and stable heat output, making them ideal for applications that require efficient and rapid heating.

Reheatek offers two main types of cartridge heaters: Common Cartridge Heaters and Power Distributed Cartridge Heaters. Each is designed for different heating equirements and application environments.

Common vs. Power Distributed Cartridge Heaters — What’s the Difference?

Common Cartridge Heaters

Common cartridge heaters are suitable for most general heating applications, including:

These heaters use evenly wound nickel-chromium heating wire. This construction is simple, cost-effective, and works well in standard heating scenarios.

However, because the ends of the heater dissipate heat faster than the center, the center area tends to run slightly hotter. This is acceptable for most applications but not ideal for high-precision temperature requirements.

Power Distributed Cartridge Heaters

Power distributed cartridge heaters are specially designed for applications requiring consistent temperature distribution, such as:

Packaging sealing machines

High-precision melt-blown machine molds

Precision industrial equipment

The key difference lies in how power is distributed along the heating wire. Through engineering simulation and thermal analysis, Reheatek adjusts the winding density of the heating wire to match the expected heat dissipation of each section.

Power distributed cartridge heaters are specially designed for applications requiring consistent temperature distribution, such as:

Constant-temperature working tables for noble metal processing

Packaging sealing machines

High-precision melt-blown machine molds

Precision industrial equipment

The key difference lies in how power is distributed along the heating wire. Reheatek adjusts the winding density of the heating wire to match the expected heat dissipation of each section.

How Reheatek Achieves Controlled Power Distribution

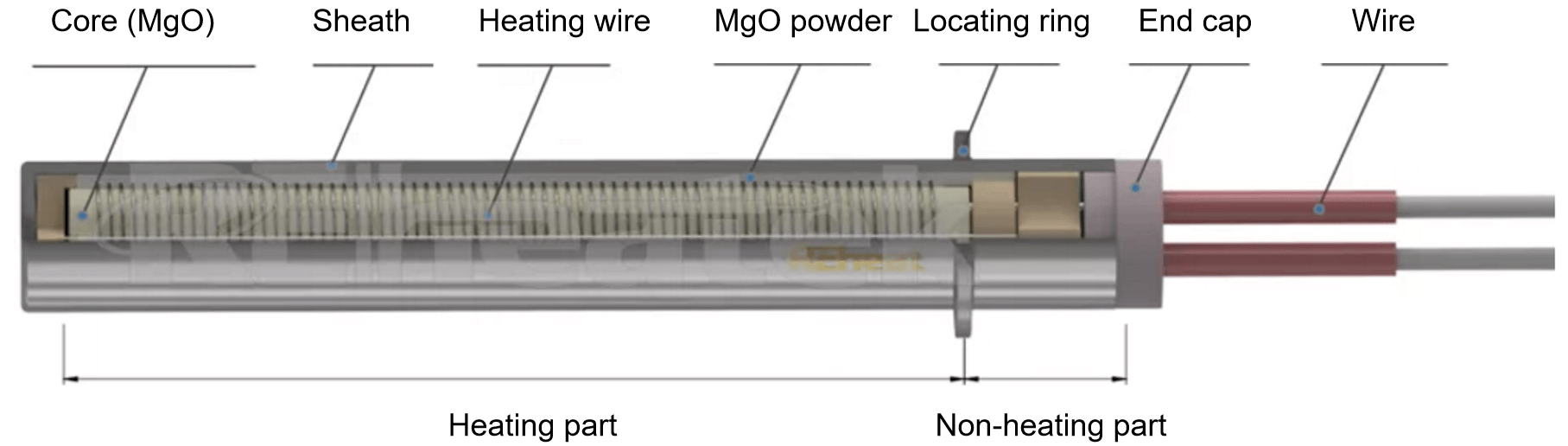

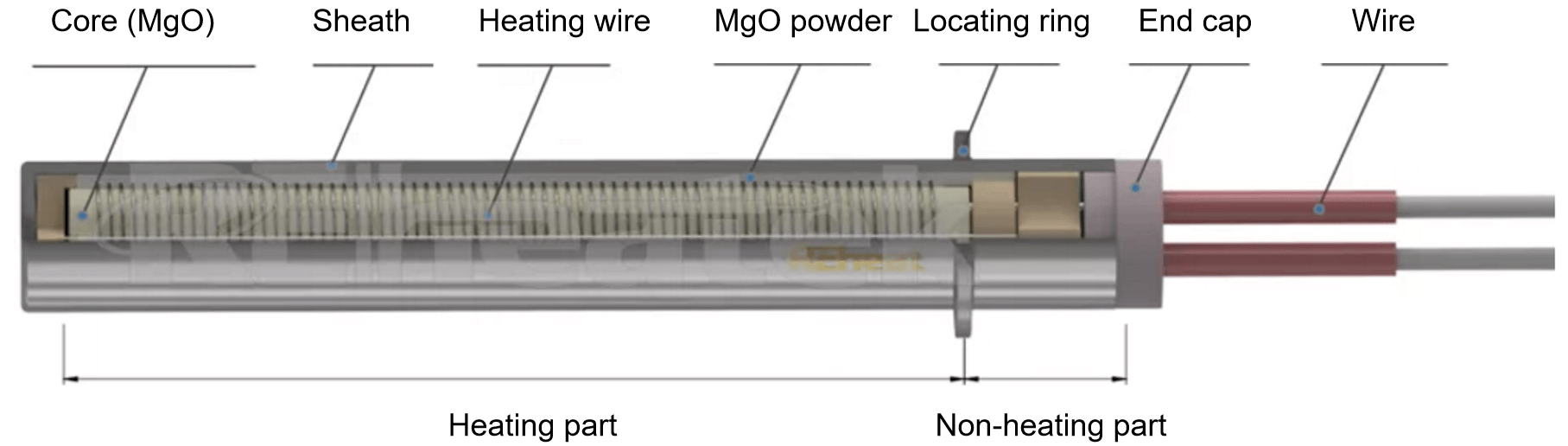

To understand this, let's first look at the basic internal structure of a cartridge heater:

A nickel-chromium heating wire serves as the heat source

Heat travels through high-purity magnesium oxide powder (MgO)

The outer metal sheath transfers heat to the target object via conduction

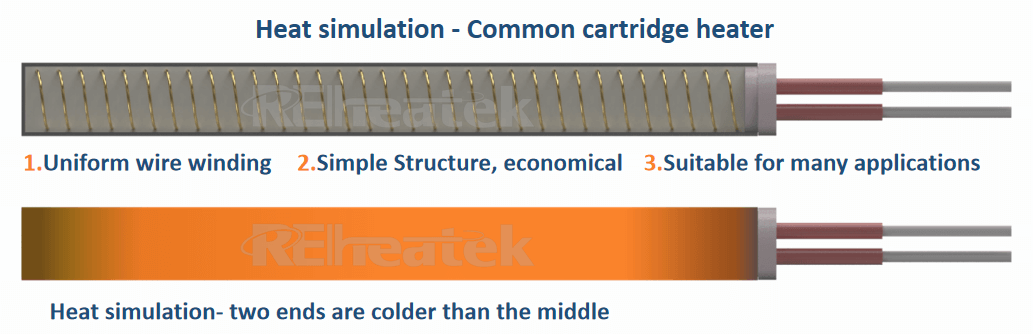

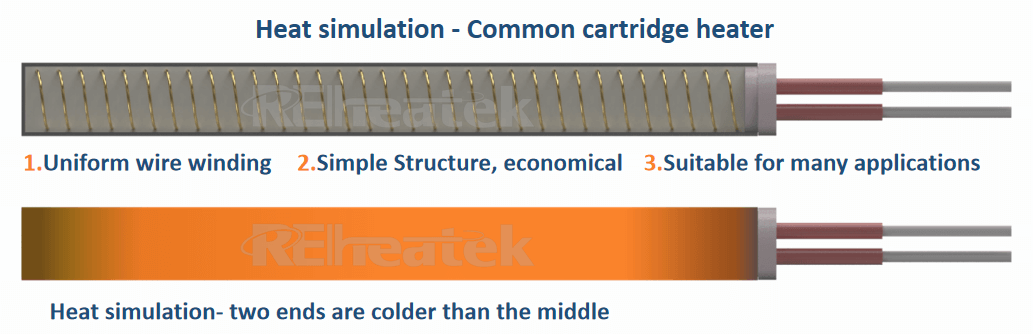

Common Cartridge Heater Structure

Heating wire is wound evenly

Ends dissipate heat faster than the center

Results in a slightly hotter center section

Suitable for general applications but not precision heating

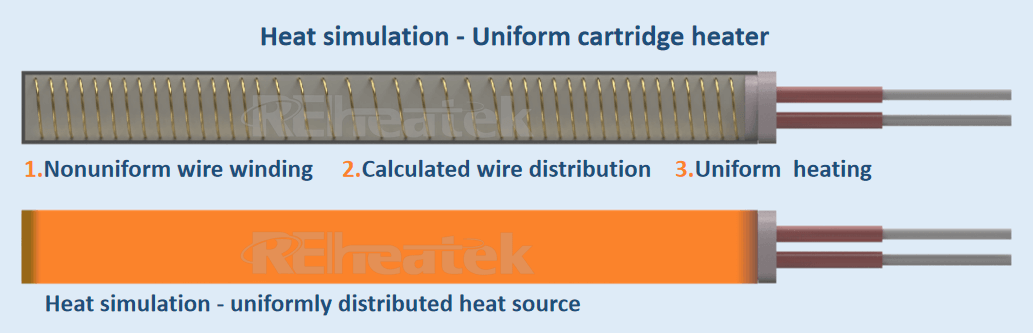

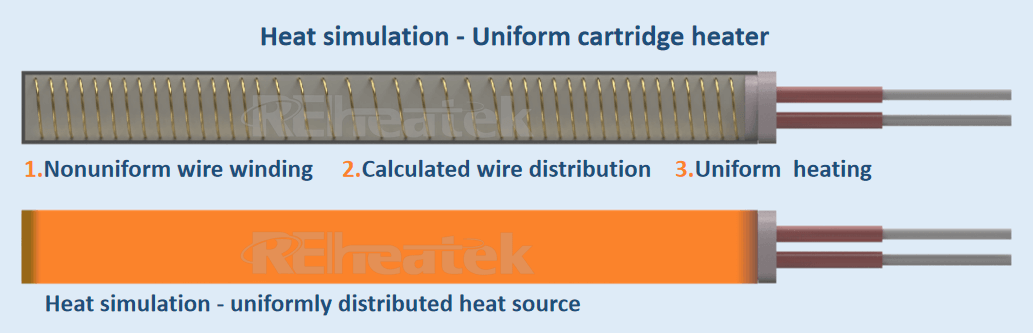

Power Distributed Cartridge Heater Structure

Reheatek applies a different engineering approach:

Heating wire is not evenly wound

The two ends have higher winding density, thus higher power

The center has lower density, preventing excessive heat buildup

The result is a thermally balanced heating zone

This customized power distribution ensures the entire heating section operates at nearly the same temperature.

Advantages of Reheatek Power Distributed Cartridge Heaters

1. Highly Uniform Temperature Output

Balanced power distribution results in consistent temperature across the entire heated length.

2. Improved Energy Efficiency

Even temperature output reduces thermal loss and improves heating efficiency.

3. Ideal for Precision Applications

Especially suitable for molds and high-precision equipment that demand strict temperature uniformity.

Conclusion

Both common and power distributed cartridge heaters are indispensable in industrial heating.

Common cartridge heaters are versatile and economical for standard applications.

Power distributed cartridge heaters provide a controlled, uniform, and stable heat profile, meeting the demands of high-precision processes.

Reheatek will continue to deliver more efficient and energy-saving heating solutions to customers worldwide.