In the past years communicated with our customers, we often received from clients that the cartridge heaters they used before has a short service life.

Below are some reasons based on our work experience for reference

1. Low-cost products are in high-temperature equipment

Product quality varies from the low end to high end cartridge heaters. Low end cartridge heaters may be only a few dollars while and high end cartridge heaters may be much higher. Materials are one of the reasons which cause the price and service life differences.

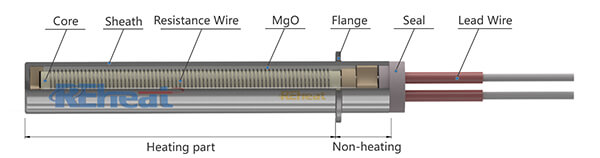

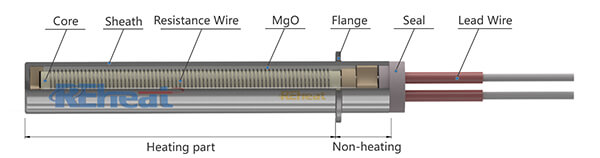

Sheath material:

Under high-temperature sheath surface will oxidize and becomes black. Improper usage of unsuitable sheath will accelerate the oxidation and shortens the service life. Incoloy 800 is a better option to use in higher temperature.

Resistance wire:

Resistance wire will when working. High temperature will accelerate the oxidization, so it’s important to use the resistance wire could withstand higher temperature.

MgO:

MgO is the insulation material resistance wire, filling the space to avoid short between sheath and resistance wire. It should effectively transfer heat to the sheath. High purity MgO is a must especially in high temp.

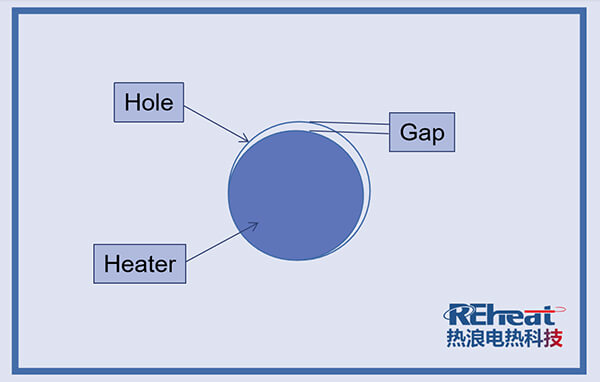

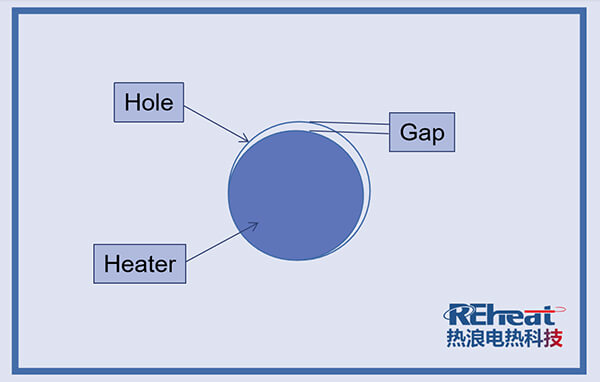

2. Improper fit when install to the mold hole

Improper fit is the most common cause shortens cartridge heater failure. The hole within which they are inserted must be held to tight tolerances. High watt density cartridge heaters are even more sensitive as the internal temperature of the heater can rise rapidly and jeopardize the life of the heating element. Usually the gap between the two is less than 0.1mm. For a cartridge heater with a diameter of 10mm, it should be a hole within 10.1mm.

3. Moisture

Cartridge heaters are prone to failure when the air surrounding the heater contains impurities or has a high moisture content when the heater’s leads are not adequately sealed. Due to the nature of MgO insulation: it is highly hydroscopic powdered mineral. When the heater undergoes thermal cycling a vacuum is created, drawing in moisture or other contaminants such as oil, which can result in internal shorting.

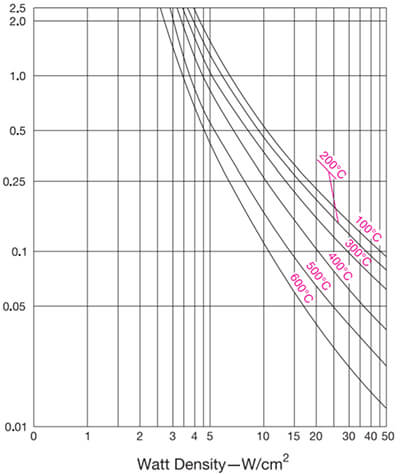

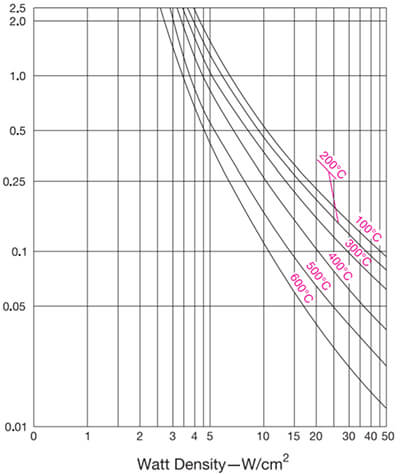

4. Incorrect Watt Density

The watt density of the heater is vital to the performance. Higher watt density requires better thermal dissipation. High watt densities will lead to shorter life when thermal dissipation needs are not met, as the internal temperature of the heater will exceed the limits of the resistive heating element.

5. Incorrect Supply Voltage

In a resistive circuit, the resistance is fixed, when the voltage is doubled, the current doubles as well as quadrupling the wattage output. Incorrect supply voltage can lead to premature heater failure.

The above is the analysis of the reason for the shortened life of the cartridge heaters in stock.If you encounter any problems, please feel free to send us an inquiry, we will do our best to help you solve the problem.