Flange immersion heater is a type of immersion heater, which has a wide range of applications and is suitable for heating up various liquids.

Flange immersion heater with thermostat is flange immersion heater with built-in temperature control unit (thermostat), which can detect the temperature of the heating medium and realize overheat power-off protection, improving the energy-saving effect and safety of the product.

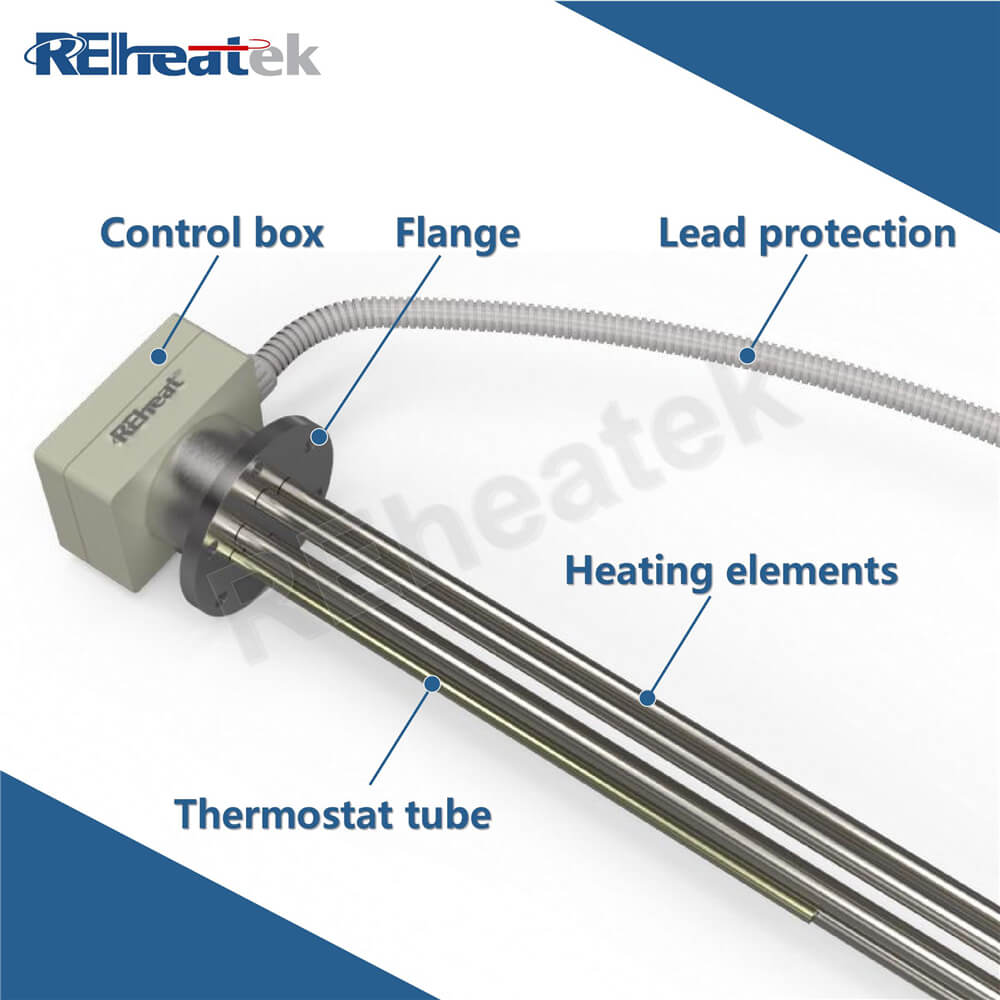

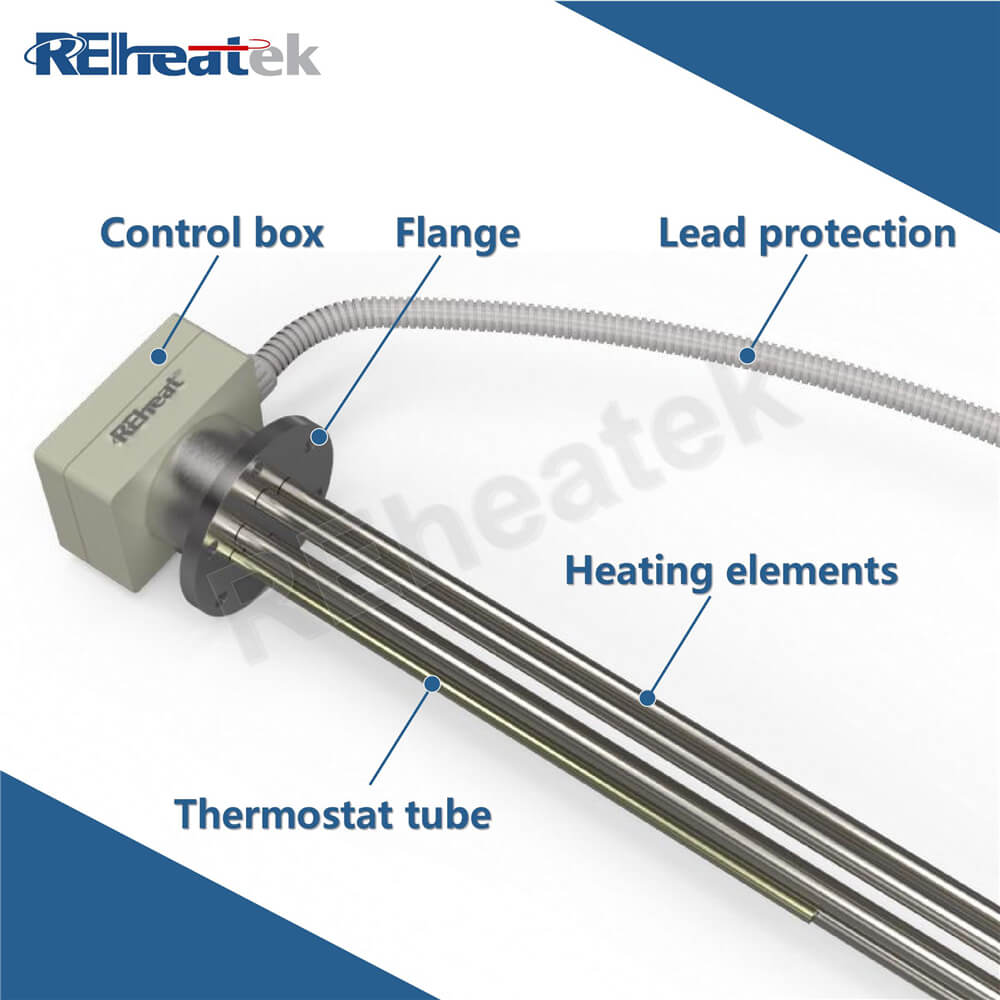

It is composed of heating elements, thermostat tube, flange, control box and leads. Material of the heating elements and flange can be chosen according to the properties of the liquid. The control box is easy to disassemble and install, which can effectively protect the thermostat and prevent accidental touch.

Flange immersion heater with thermostat can be customized not only in terms of the material of heating elements and flange, but also in terms of power, voltage, flange external diameter, immersion length, etc.. Available product parameters for reference: Power-10kW, voltage-3phase 380V, immersion length 900mm. It can heat 10kg of water from room temperature to 100°C in 5 minutes, REheatek provides calculation service. See below for more details.

The temperature control unit with built-in temperature-controlled flange heating elements is knob-based and simple to operate.

Overheat protection device installed on the immersion heater help to prevent the heater from dry heating when there is no liquid, and greatly protect the heater. Because immersion heaters are designed for use in a liquid environment, dry heating will cause the surface power load of the product to increase, affecting the product service life and may immediately burn out the heating element in severe cases.

OPTIONS

FLANGE HEATERS

Mounted on the side of tanks, it is extremely strong and provides excellent heat. Flange plate size, thickness and shape are determined by the application.

OVER THE SIDE HEATERS

A practical method of heating open tanks from the top (typically). It offers the ability to use this heater for multiple tanks while other immersion heaters can't be conveniently installed.

SCREW PLUG HEATERS

These heaters screw into your tank and provide heat to liquids in smaller tanks and compartments. They are installed into threaded openings or couplings in the tank or vessel.

CORROSIVE LIQUID HEATERS

Corrosion resistant sheath materials and special surface treatment are available so the heaters could be used in corrosive environments and have longer service life.

THERMO CONTROL

In order to achieve temperature control, overheat protection and longer life of the heaters, a thermostat or thermocouple could be integrated into the heaters.

CUSTOM NON-HEATING PARTS

No-heat parts could be customized for different applications.