Many times the heater will have some failure, so we need to understand the cause of the failure in the end what.

Causes of premature equipment failure

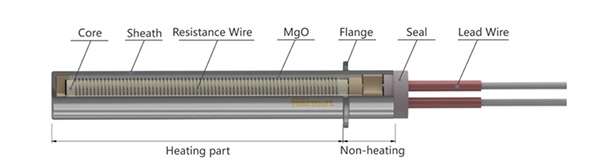

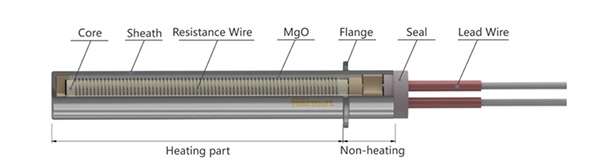

Premature cartridge heater failure occurs when the heat generated in the internal resistance wires is not dissipated efficiently, or when moisture or foreign matter seeps into the casing and causes a short circuit. Insufficient heat dissipation will lead to an increase in internal temperature, which will lead to rapid aging of heating elements. This can occur when machining tolerances exceed acceptable limits, the power density is too high, or is powered by the wrong supply voltage.

For the cartridge heater failure, our cartridge heater manufacturer for the cause of the failure to do some analysis.

Improper fitting

Improper installation is the most common cause of premature cartridge heater failure. It must be inserted into the borehole to maintain a strict tolerance. Cartridge heaters with high power density are more sensitive because the temperature inside the heater can rise rapidly and endanger the life of the heating element. To ensure adequate heat dissipation, it is recommended that the aperture not exceed the nominal diameter of the heater by 0.002 inches.

The typical allowable power density of forged drum heaters is based on fit and operating temperature.

Power supply voltage error

In a resistance circuit, the resistance is fixed, so when the voltage is doubled, the current will double and the power output will triple. Incorrectly specifying the supply voltage can cause the heater to fail prematurely because the voltage can have a huge effect on the power and heat generated, as shown in the following formula.

Moisture or invasion

Even when drum heaters have helically welded end caps, they are prone to failure if the air around the heater contains high amounts of impurities or moisture and the heater wires are not adequately sealed. This is due to the nature of the MgO insulation: it is a highly hygroscopic white powdery mineral that forms a vacuum when the heater is in thermal circulation and absorbs water or other contaminants (such as oil), which can cause an internal short circuit.

Incorrect wattage density

The power density of a heater is critical to its performance.Cartridge Heater Manufacturers are relatively strict in this regard This is a measure of thermal power density, and the higher the watt density, the greater the need for heat dissipation. When heat dissipation requirements are not met, high power densities can lead to premature failure, as the heater's internal temperature will exceed the limit of the resistive heating element.

Tight fit tolerance

Tight fitting tolerances are the most important factors affecting the heat transfer rate and the life of the heating element. Tight coordination allows the user to achieve high efficiency while keeping the heating element as cold as possible. When finishing or reaming boreholes or casting holes, extra care should be taken to ensure smooth surfaces, thereby increasing the contact surface area between the heat transfer equipment and the cartridge heater.

Do you need help in case cartridge heaters fail?

If you don't know how to solve the problem of cartridge heater, you can contact Reheatek .