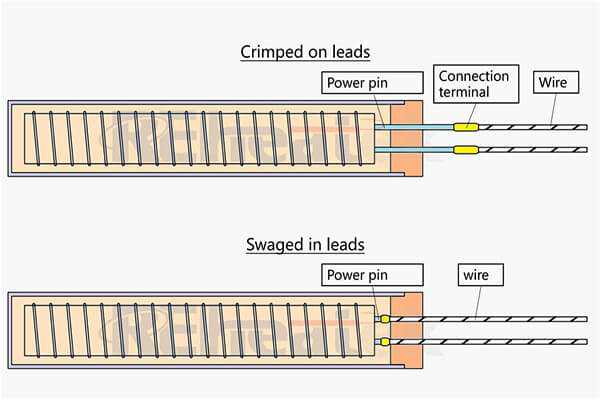

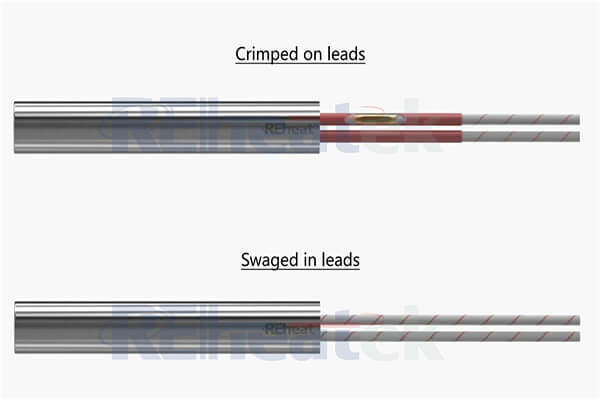

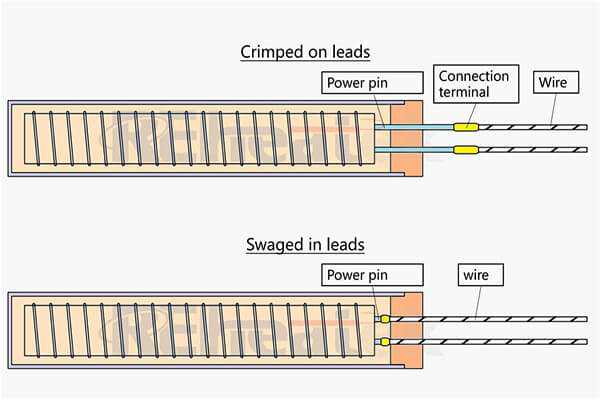

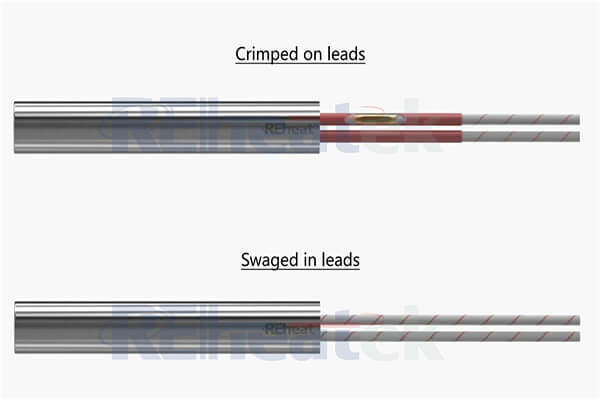

When purchasing a cartridge heating element, users will always ask a question: "What is crimped on leads (external lead) and what is the swaged in leads (internal lead)? What is the difference between these two constructions?" Let's take a brief look at the crimped on leads (external lead) and the swaged in leads (internal lead) :

1. Structure and characteristics

It can be clearly seen from the above figure that the construction of the crimped on leads and the swaged in leads are different. The crimped on lead structure is that the power pin and the wire are connected by connection terminal outside the heater, while in the swaged in lead structure, the lead is directly connected from the inside. Crimped on lead structure usually uses glass fiber sleeves to increase insulation protection, and to avoid excessive bending. The power pin of swaged in lead structure does not extend outside, lead wire and power pin need to be connected before sealing. Ceramic end cap or glue are used to seal the heater. The production process is more complicated and time-consuming than the crimped on lead structure. Therefore, the price of the swaged in heater is usually more expensive than the crimped on heater.

2. Notes of the two construction

a. No excessive bending at the outlet of the crimped on lead structure.

The material of the power pin is generally hard nickel which is difficult to bend. If the lead connected is bended too much, connection terminal will loose easily, and causing circuit, leakage, etc. .

b. Swaged in construction lead shoule be at least 500℃ heat-resistant. Since it's connected inside the heater, it needs to withstand a high temperature during work, otherwise it will be easily burnt out during use.

c. For cartridge heaters with crimped on structure, leads should not be exposed to high temperature environment.

It is generally not necessary to use high-temperature wires, maximum temperature resistance is generally around 200°C, it cannot be used in places with high ambient temperature. If it's needed to use it in a high-temperature environment, please inform the manufacturer in advance to choose more suitable materials.

d. Leads of any construction are not allowed to be dragged forcefully. The leads can withstand a certain pulling force, but the connection will be damaged easily with too strong pulling force, which is very unsafe.

e. Check the status of leads regularly.

When using the heaters in mechanical equipment, debris such as oil, corrosive liquids or foreign particles may accidentally fall on the lead. When heats continue to work in a high-temperature environment for a period of time, these debris may be carbonized and agglomerated. It may also corrode the fiber glass sleeve on the lead, which is very easy to cause short circuit of the device and has great potential safety hazards. It's necessary to check the lead status regularly, turn it off when it is dirty and wait for cooling after treatment.

f. Equipment with high technological requirements, regularly replace the heater.

Although good quality heaters can be used for a long time, some can even be used for more than ten years, the heating performance in a complex environment will be greatly reduced. If the process requirements of the product are high, please replace heaters regularly.

3.How to choose the right cartridge heater?

a、Lower power, lower temperature - Crimped on construction

b、Longer lead wire - Crimped on construction

c、Thinner and shorter heater - Crimped on construction

d、LImited space for outlet and wiring- Swaged in construction

e、Leads will be bent or moved frequently - Swaged in construction

f、Higher operating temperature- Swaged in construction with high temperature resistant lead wire

g、When used in an environment with heavy oil pollution or corrosive gas- Swaged in construction withTeflon lead wire

The choice of structure is related to many details.

If you don’t want to choose yourself, please contact us and tell us about the application environment of the products. Reheatek will customized professional heating solutions for you and provide high-quality products. I believe that through our description, you could have a preliminary understanding of crimped on and swaged in construction. Heater wire construction is not only related to the processing technology, but also related to the application environment. It's important to choose a good and professional cartridge heater manufacturer!