In industrial applications, many heating elements are usually used together in groups. How to wire these heating elements to realize the required heating effect become a topic of concern.

Two basic knowledge:

1. The wiring of heating elements doesn't require to distinguish positive and negative poles.

The core heating element of electric heaters is resistance wire (normally nickel-chromium alloy - Ni80Cr20), which is a resistive element, so there is no distinction between positive and negative poles.

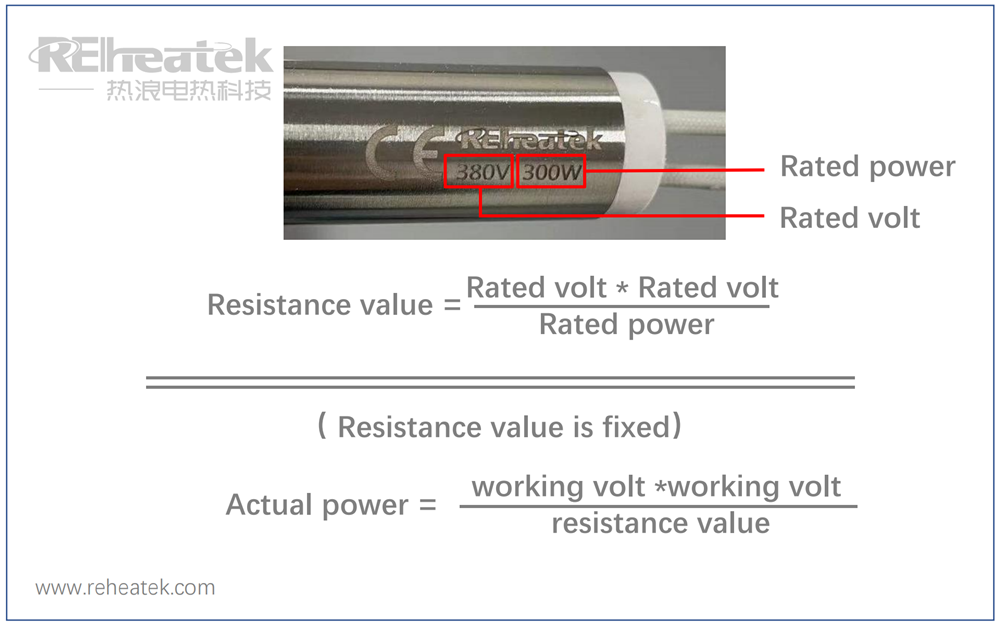

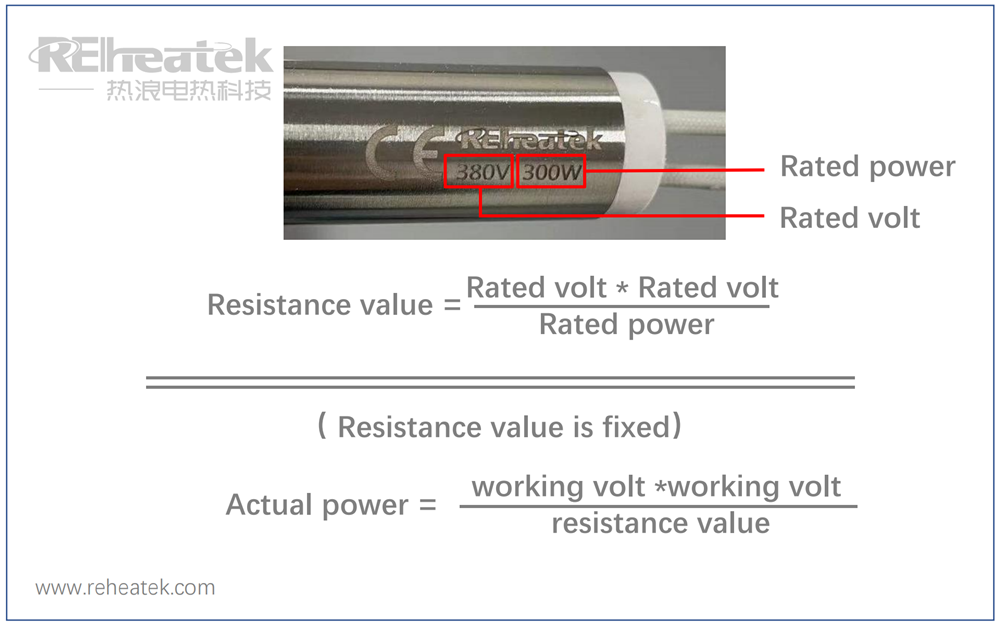

2. The resistance value of the heating elements is fixed.

Resistance value = Rated volt * Rated volt/ Rated power

(Rated volt and power are confirmed, resistance value can be fixed by volt and power.)

Actual power = Working volt *Working volt / Resistance value

Based on above formula, operating voltage changes actual power. Wrong voltage input will lead to failure of heating elements even safety problems. Please always operating heaters with rated voltage.

Below are some common wiring methods:

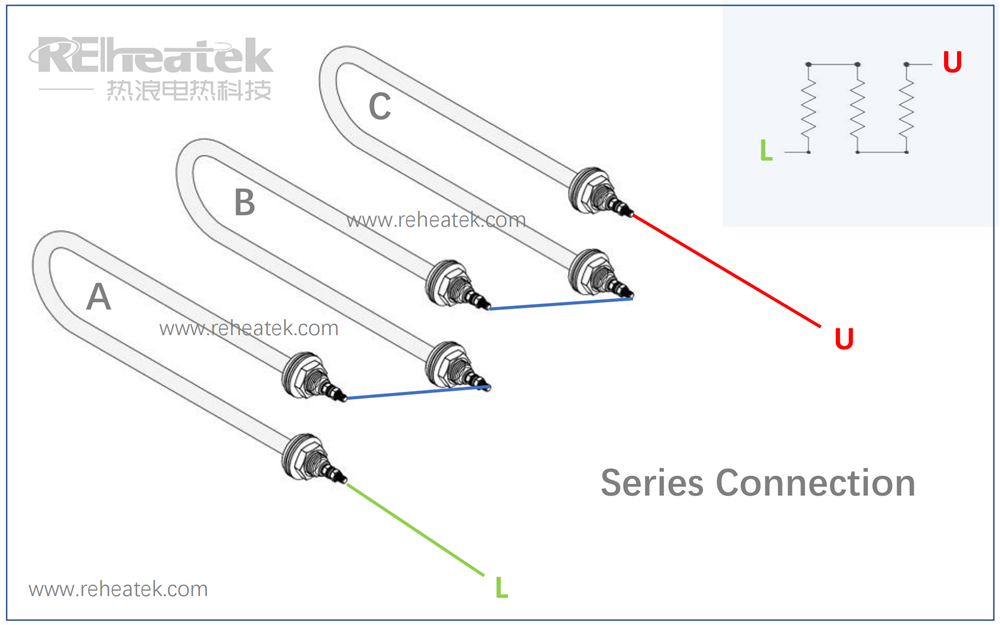

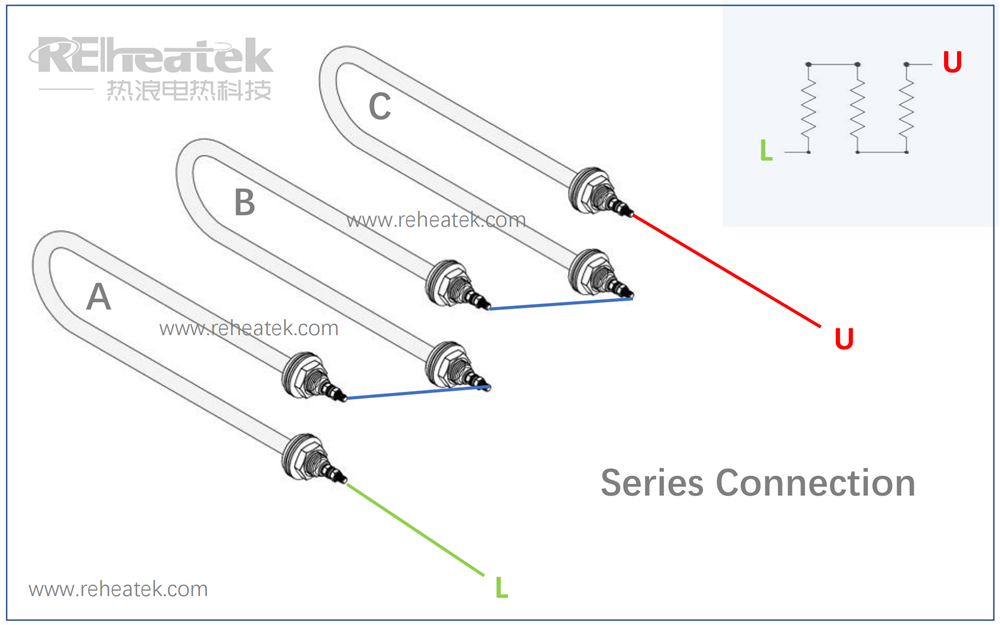

1. Series Connection

Series connection is one of the basic wiring types, simply connect heaters from end to end as above picture.

In series connection, each heating element has the same current (Current = Voltage / Resistance value.). If many elements with different resistance value are connected in series, voltage for single element = current * resistance value of the element.

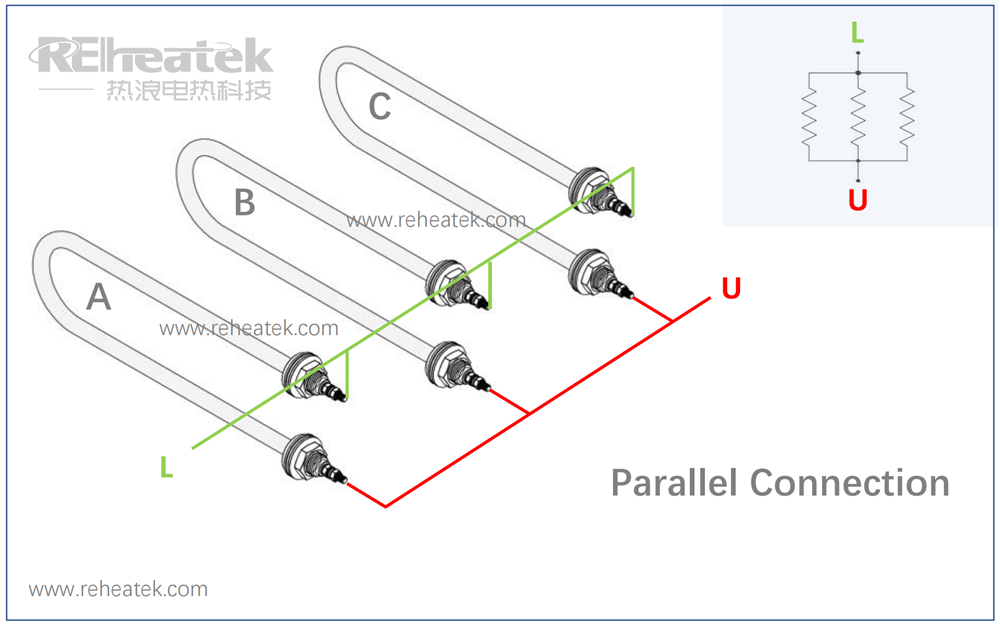

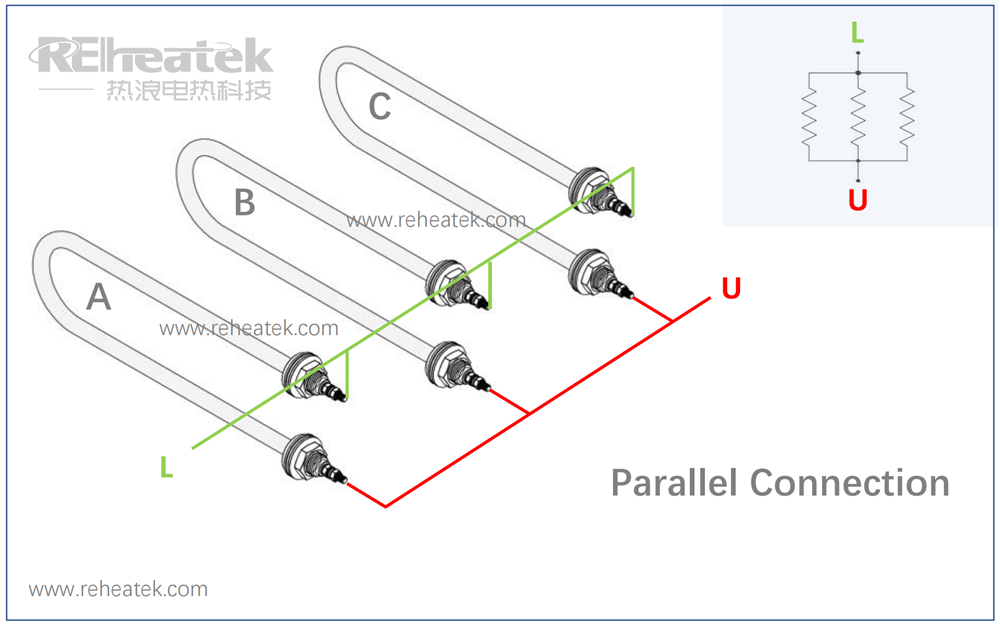

2. Parallel Connection

Connect one end of each heater together, and then the other end as the above picture.

In parallel connection, each heater has the same voltage and different current based on resistance value. For example as in the figure, current in A element = Voltage / Resistance Value A.

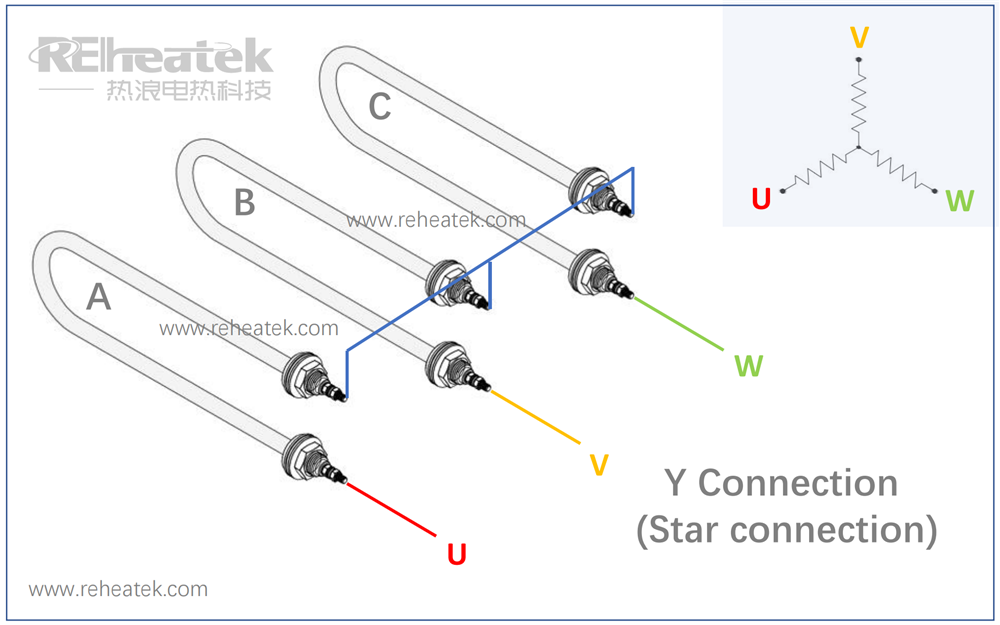

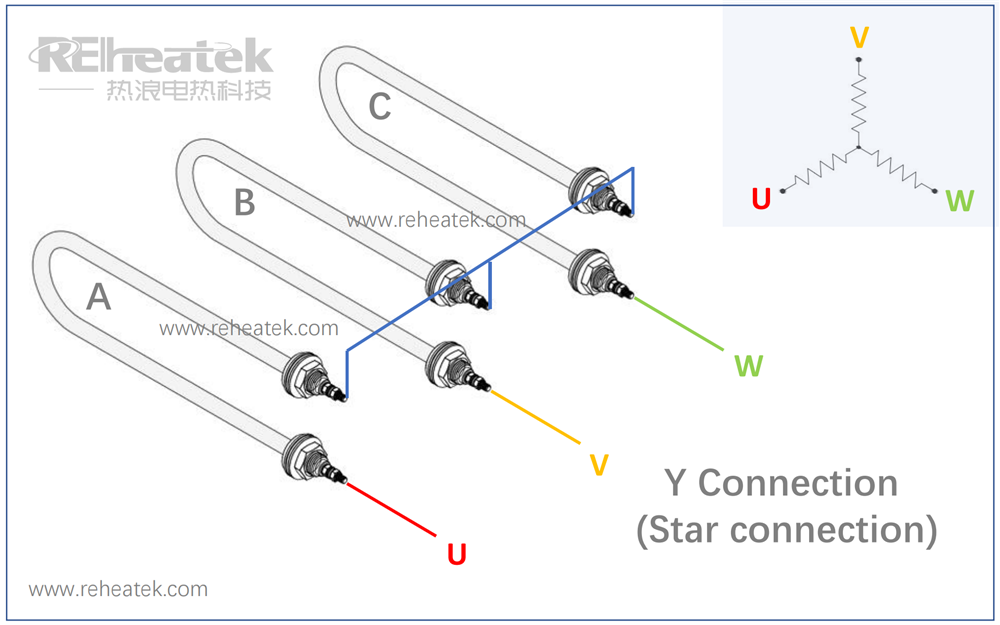

3. Y Connection (Star connection)

A star connection is a connection used in AC three-phase power supply. Star connection is to connect one end of each heater to a common junction, and the other end to a separate terminal as above figure in U, V, & W.

In star connection, the line current is equal to the phase current, and the phase voltage is equal to √3 times the line voltage.

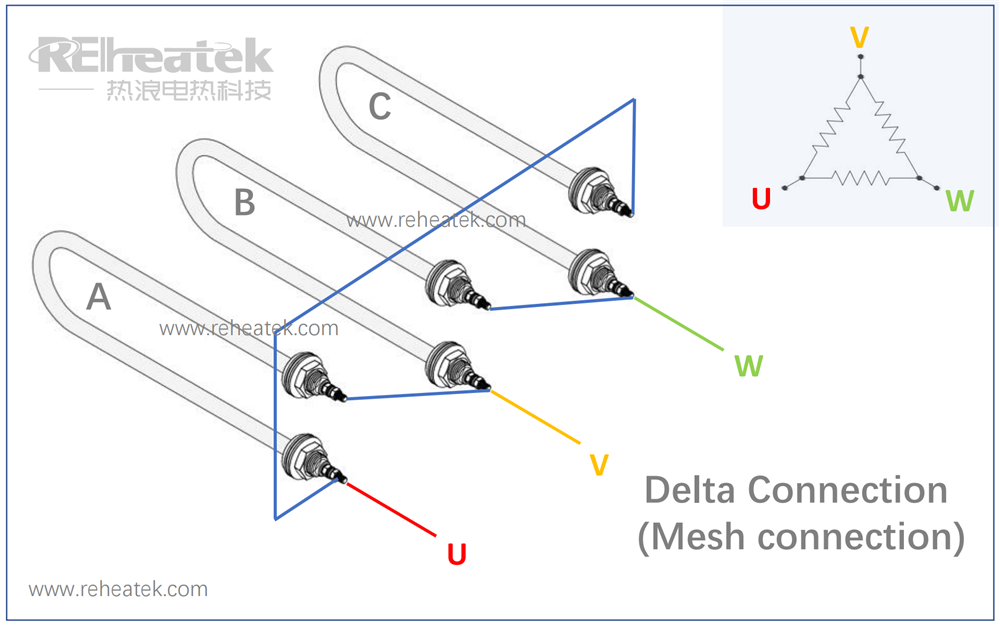

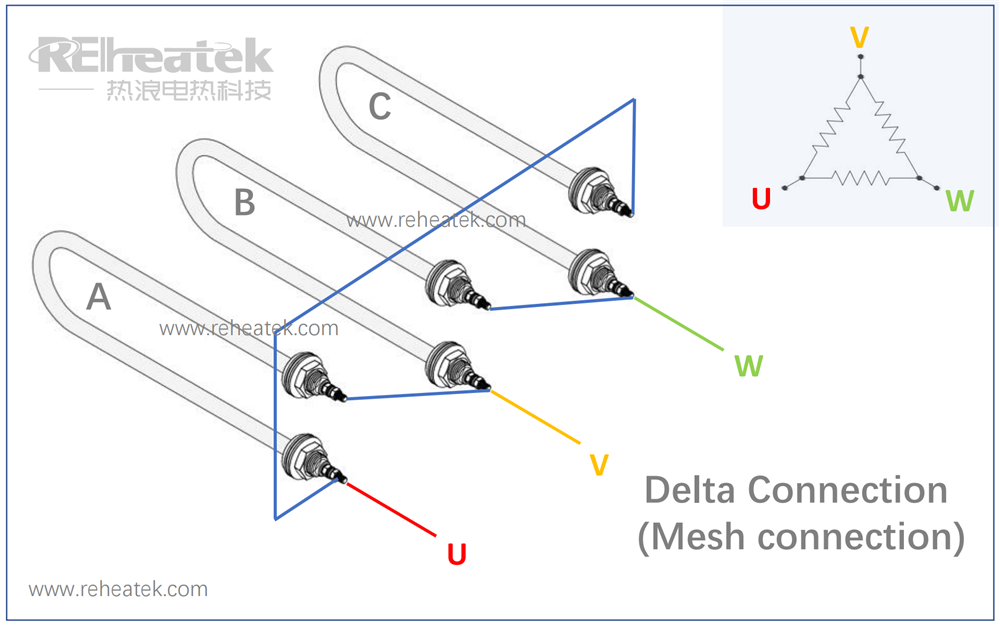

4. Delta Connection (Mesh connection)

Delta connection is also used in AC three-phase power supply. To obtain Delta connection, each heating element is connected end to end, then three common points U, V & W form the three phases. The delta connection has no neutral point, and it cannot lead to a neutral line, so there is only a three-phase three-wire system. In Delta connection 3-phase system, line voltage is the same with phase voltage, and the line current is equal to √3 times the phase current.

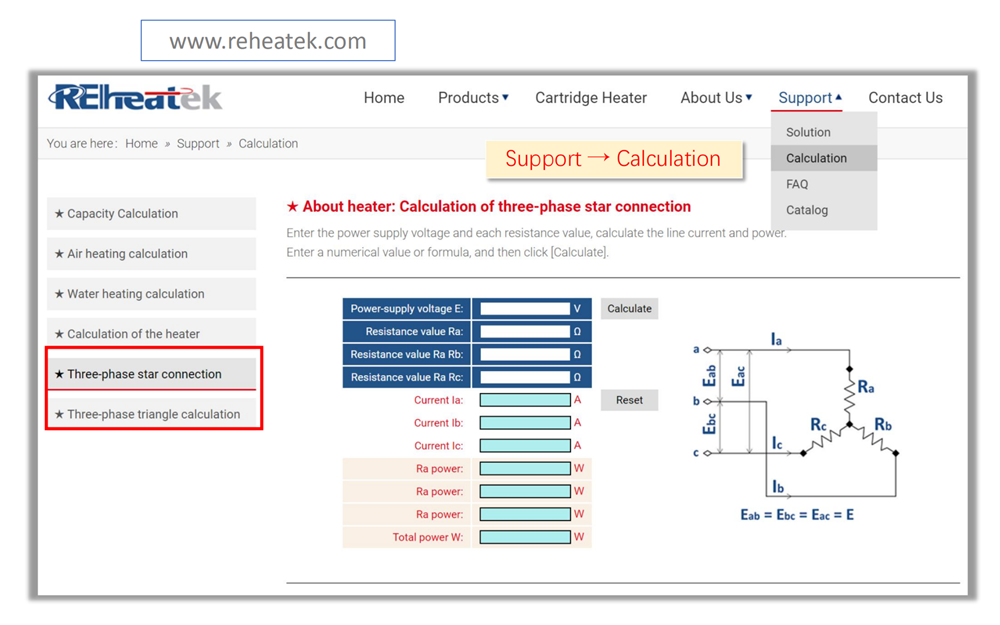

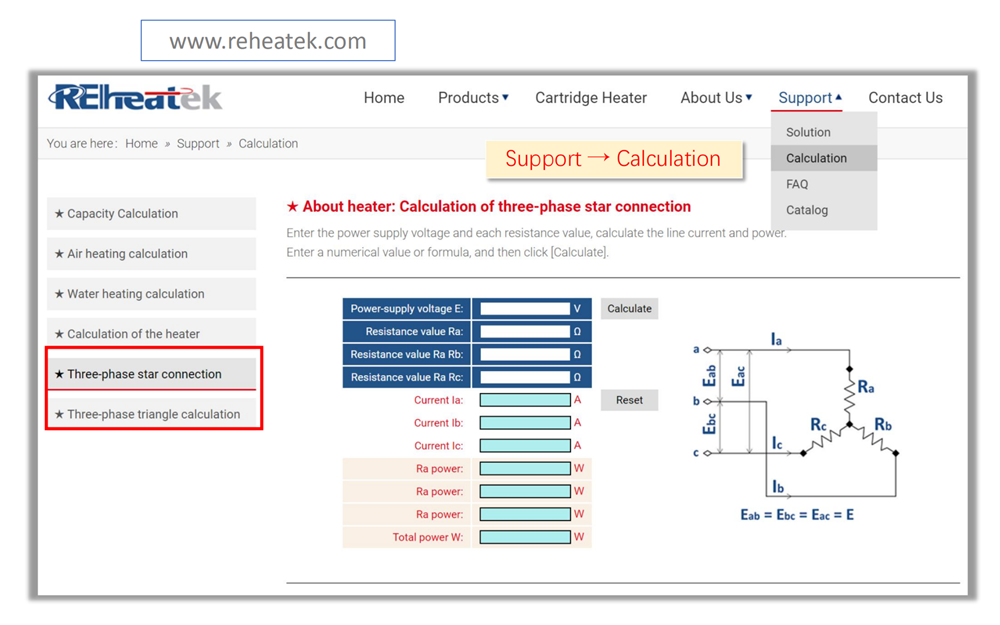

Current & voltage calculation of each heating element with different power connected in 3-phase

It is more complicated to calculate the current or actual power output of heating elements with different power (different resistance value) when it's used in 3-phase voltage.

REheatek official website provides technique support for self-calculation as below:

Website: www.reheatek.com → Support → Calculation → Three phase Star/ Triangle calculation.

Notes

Please advise REheatek sales or engineer the connection method before customization heating elements.

Precaution: Please operate heating elements with rated voltage. Wrong voltage changes power, which will lead to heater failure or severe accidents.

Wiring the heating elements you already have

Pay attention to the rated voltage of the heater before operation. For example in China, standard 3-phase is 380V. If the heating elements rated voltage is 380V, then heaters should use Delta connection. If rated voltage is 220V, then it should be Y connection (star connection).