Overview

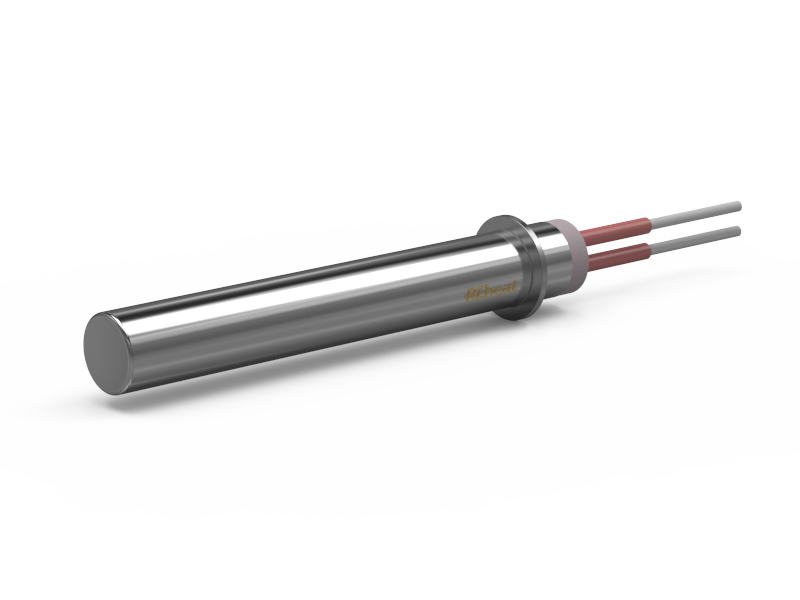

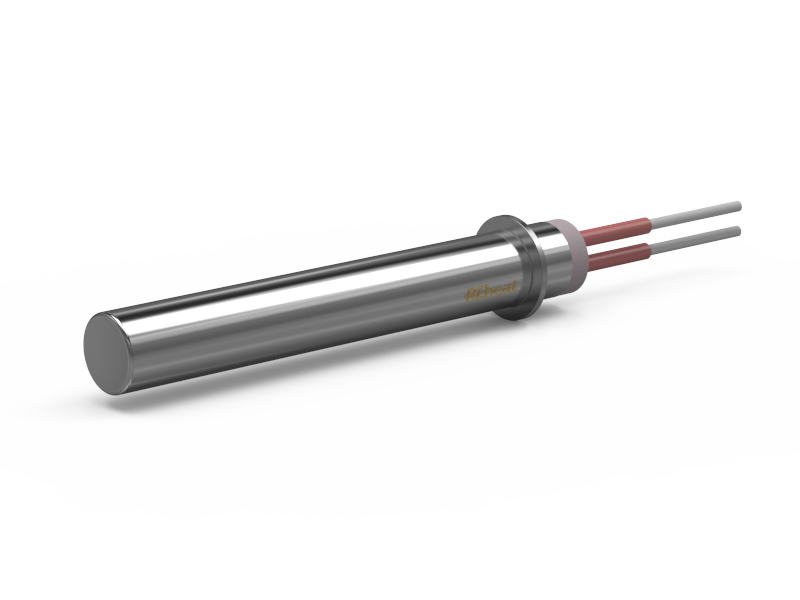

This design allows for direct heat transfer into molds, dies, and other workpieces, providing accurate temperature control and uniform heating. Cartridge heaters are widely used in industries such as plastics, metals, and manufacturing, where precise heating is essential for optimal process performance.

Features

Efficient and Direct Heat Transfer: By inserting the heater directly into the workpiece, cartridge heaters provide direct and efficient heat transfer, minimizing energy loss and ensuring uniform heating.

Precision Temperature Control: These heaters allow for precise temperature regulation, maintaining consistent temperatures within tight tolerances. This is crucial for processes like plastic injection molding and die casting.

Durable and Reliable Construction: The metal sheath and ceramic insulator protect the heating element from mechanical damage, corrosion, and electrical shorts, ensuring long-term reliability.

Customizable Specifications: Available in various lengths, diameters, and wattages to suit different application requirements. Custom designs, including special voltage ratings and termination options, can be provided.

Fast Heating and Cooling: Cartridge heaters offer rapid heat-up and cool-down times, enabling quick response to temperature changes and improving process efficiency.

Easy Integration: Designed for simple installation into pre-drilled holes, these heaters are easy to integrate into existing equipment and systems.

FAQ

What are the typical applications for cartridge heaters?

Cartridge heaters are commonly used in plastic injection molding, die casting, heat treatment, and other industrial processes requiring precise and uniform heating.

How do I ensure proper installation of a cartridge heater?

Ensure the heater is fully inserted into a properly sized pre-drilled hole. Use a wrench to tighten the screw plug or terminal box securely. Avoid twisting the heater during installation to prevent damage.

What should I do if my cartridge heater fails to heat?

Check for loose electrical connections, damaged wiring, or a faulty heating element. If the heater shows signs of wear or damage, it may need to be replaced.

Can cartridge heaters be used in high-vibration environments?

Yes, but proper securing and vibration-resistant designs are recommended to prevent damage and ensure reliable performance.

What is the expected lifespan of a cartridge heater?

With proper installation, usage, and maintenance, cartridge heaters can last several years. Factors such as operating temperature, environment, and thermal cycling will affect their lifespan.