Overview

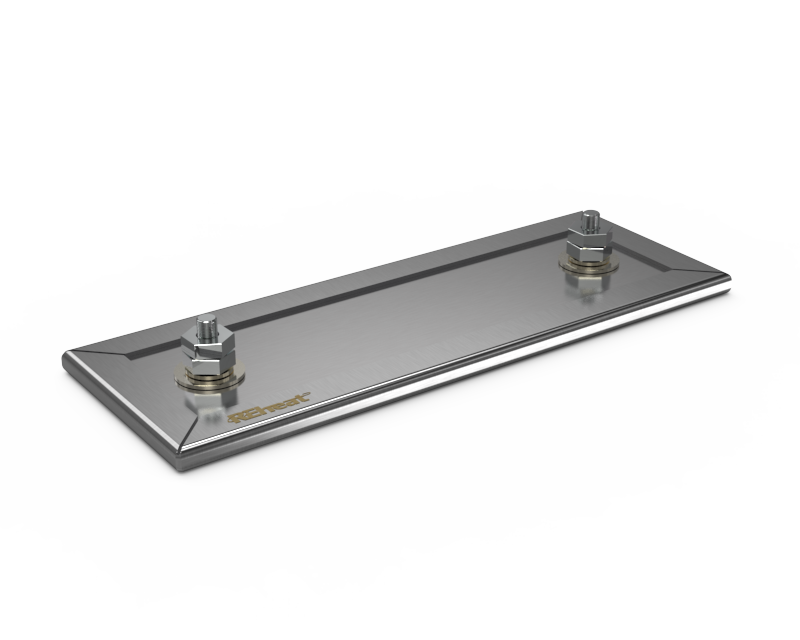

These heaters are typically made from high-quality materials such as stainless steel or aluminum, ensuring durability and longevity. Strip heaters are designed to provide uniform heat distribution over a large surface area, making them ideal for applications like mold heating, pipeline heating, and drying processes. Their compact and flexible design allows them to be easily mounted on flat or curved surfaces, providing a customized heating solution for different industrial needs.

Features

Uniform Heat Distribution: Strip heaters provide even heat distribution across the entire surface, eliminating hot spots and ensuring consistent heating performance.

Durable Construction: Made from high-grade materials, strip heaters can withstand high temperatures and harsh operating conditions, ensuring long service life.

Flexible and Customizable: The heaters can be easily bent or shaped to fit different surface contours. Custom designs are also available to meet specific application requirements.

Fast Heating and Cooling: Strip heaters offer rapid heat-up and cool-down times, allowing for precise temperature control and reducing energy consumption.

Easy Installation and Maintenance: With simple mounting options and minimal maintenance requirements, strip heaters are easy to install and keep in optimal condition.

Energy Efficiency: Efficient heat transfer and minimal heat loss make strip heaters highly energy-efficient, reducing operational costs.

FAQ

What is the maximum temperature that strip heaters can reach?

The maximum temperature varies depending on the material and design. Most strip heaters can operate up to 400°C (752°F), while high-temperature versions can reach up to 600°C (1112°F).

Are strip heaters suitable for outdoor applications?

Yes, strip heaters can be used outdoors, but proper protection from the elements is recommended to extend their service life.

Can strip heaters be used with temperature controllers?

Yes, strip heaters can be integrated with various temperature control systems, such as PID controllers, to achieve precise temperature regulation.

How do I clean a strip heater?

Regular cleaning with a soft cloth and mild detergent is recommended. Avoid using abrasive materials that could damage the heater's surface.

What is the expected lifespan of a strip heater?

With proper care and maintenance, strip heaters can last several years. Factors such as operating temperature, environment, and usage patterns will affect their lifespan.