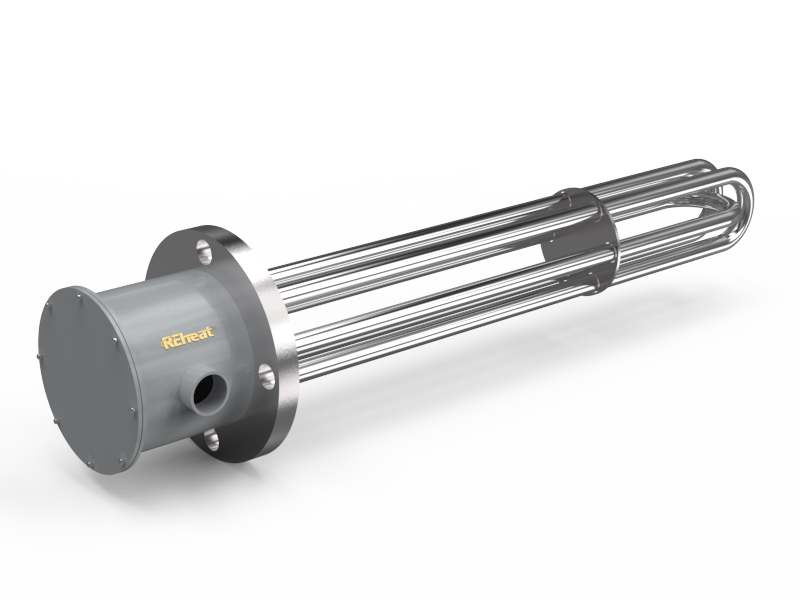

Overview

This direct immersion ensures rapid and efficient heat transfer, making immersion heaters ideal for applications such as water heating, chemical processing, and food preparation. Their robust construction and versatile design allow them to operate effectively in various industrial and commercial settings.

Features

High-Efficiency Heating: Immersion heaters provide rapid and direct heat transfer, ensuring efficient heating of liquids and other materials.

Durable and Corrosion-Resistant: The metal sheath protects the heating element from corrosion and mechanical damage, extending the heater's lifespan.

Customizable Designs: Available in various lengths, diameters, and wattages, immersion heaters can be customized to meet specific application requirements.

Versatile Application: Suitable for heating a wide range of materials, including water, oils, chemicals, and food products. They are commonly used in industrial tanks, boilers, and processing equipment.

Safety Features: Many immersion heaters include built-in safety features like thermal fuses and over-temperature protection to prevent accidents and equipment damage.

Low Maintenance: Designed for durability and minimal maintenance, immersion heaters typically require only periodic cleaning and inspection to ensure optimal performance.

FAQ

What materials are commonly used for immersion heater sheaths?

Common materials include stainless steel, Incoloy, and Inconel. The choice of material depends on the application's temperature and chemical resistance requirements.

Can immersion heaters be used in explosive environments?

Yes, but they must be properly certified for hazardous locations and installed according to safety regulations.

How do I determine the appropriate wattage for my application?

The required wattage depends on factors such as the desired temperature, heat-up time, and the material being heated. Consulting with a heating specialist can help determine the optimal wattage.

What maintenance is required for immersion heaters?

Regular inspections for signs of wear or damage, cleaning to remove debris or contaminants, and checking electrical connections are recommended maintenance practices.

What is the typical response time of immersion heaters?

The response time varies depending on the heater's design and the application. Generally, immersion heaters can reach operating temperature relatively quickly, often within minutes.