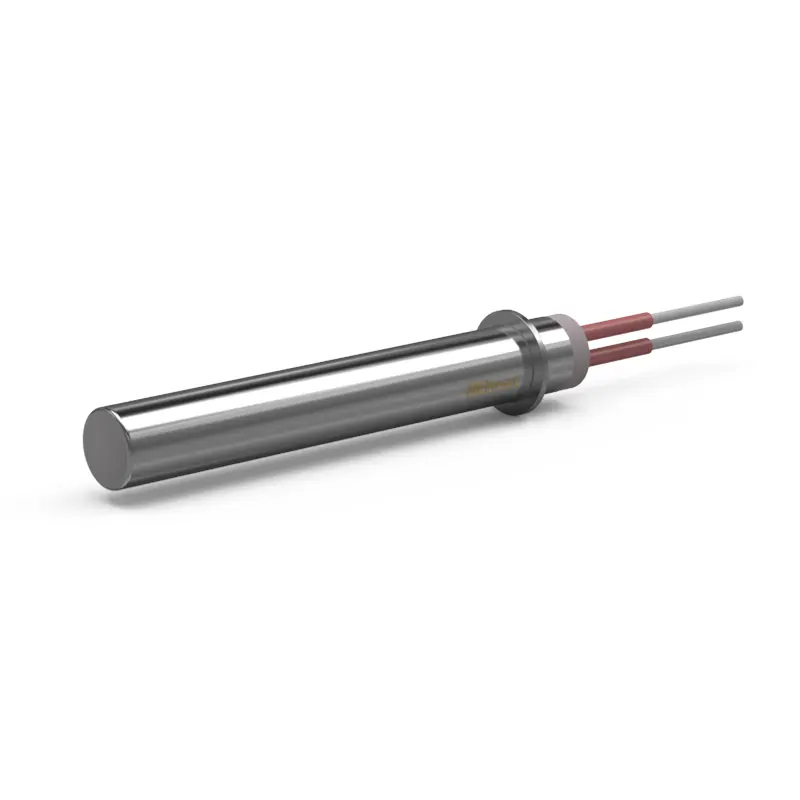

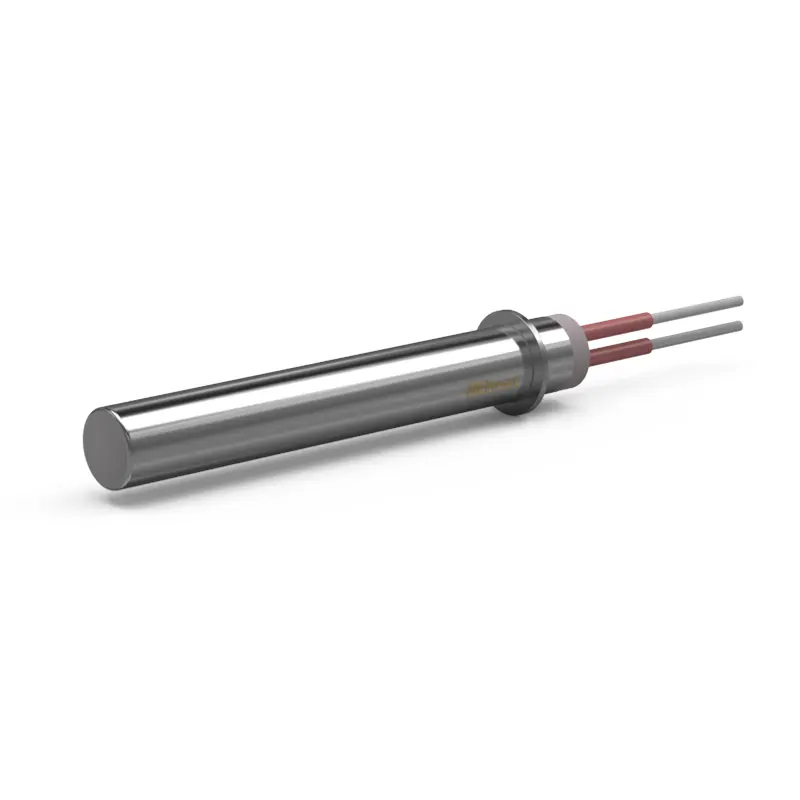

Overview

The cartridge heater is inserted into a pre-drilled hole in a mold, die, or workpiece, providing direct and efficient heat transfer. These heaters are widely used in applications such as plastic injection molding, die casting, and heat treatment, where precise and uniform heating is critical.

Features

High-Precision Heating: Cartridge heaters provide direct and efficient heat transfer, ensuring precise temperature control and uniform heating of the workpiece.

Compact and Durable Design: The small size and robust metal sheath make cartridge heaters ideal for applications with limited space and demanding operating conditions.

Wide Range of Options: Available in various lengths, diameters, and wattages to meet different application requirements. Custom designs, including special voltages and termination options, are also available.

Fast Heat-Up and Response: Cartridge heaters offer rapid heat-up times and quick response to temperature changes, improving process efficiency and reducing cycle times.

Easy Installation and Replacement: Designed for simple insertion into pre-drilled holes, these heaters are easy to install and replace. They typically feature screw plugs or terminals for secure electrical connections.

Long Service Life: The ceramic insulator and metal sheath protect the heating element from mechanical damage and corrosion, ensuring a long service life.

FAQ

What materials are used for the sheath of cartridge heaters?

Common sheath materials include stainless steel, Incoloy, and aluminum. The choice of material depends on the application's temperature and chemical resistance requirements.

How are cartridge heaters terminated?

Cartridge heaters can be terminated with screw plugs, terminal boxes, or leads. The termination method depends on the application and electrical requirements.

What is the maximum operating temperature of cartridge heaters?

The maximum temperature varies depending on the sheath material and design. Most cartridge heaters can operate up to 500°C (932°F), while high-temperature models can reach up to 800°C (1472°F).

How do I select the right cartridge heater for my application?

Consider factors such as the required temperature, heat-up time, hole size, and electrical specifications. Consulting with a heating specialist can help determine the optimal heater size and configuration.

What maintenance is required for cartridge heaters?

Regular inspection for signs of wear or damage, cleaning to remove debris or contaminants from the hole, and checking electrical connections are recommended maintenance practices.