Overview

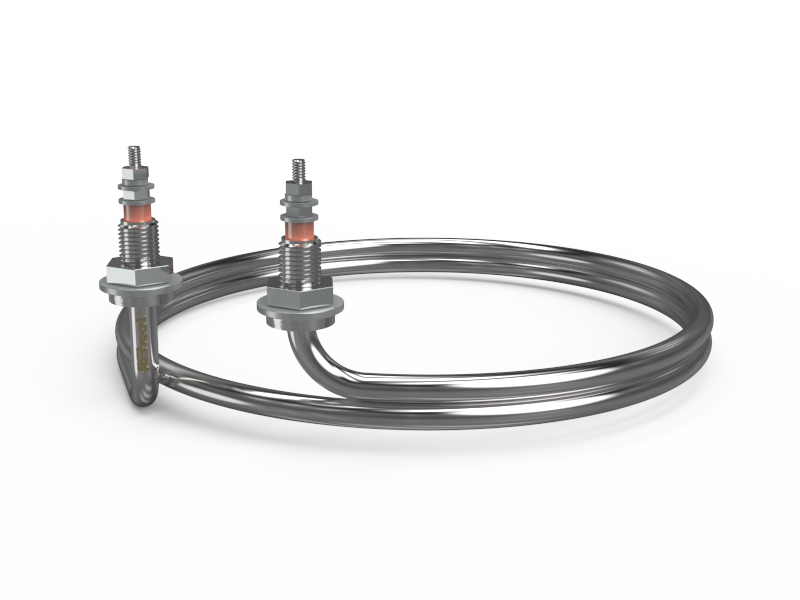

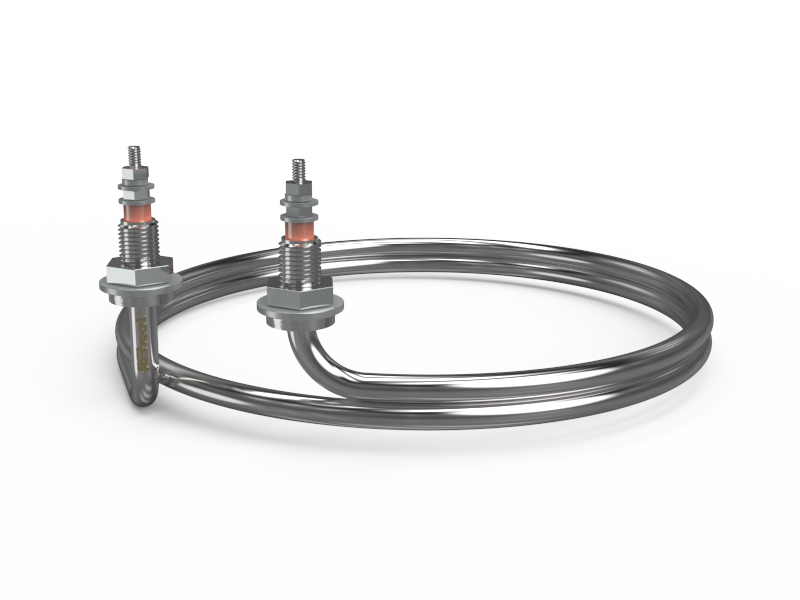

They are commonly used for air heating, liquid heating, and process heating in industries such as manufacturing, HVAC, and food processing. The compact and flexible design of tubular heaters allows them to be easily integrated into various systems and equipment, offering reliable and consistent heating performance.

Features

Efficient Heat Transfer: Tubular heaters provide rapid and uniform heat distribution, ensuring efficient heating of air, liquids, and other materials.

Robust Construction: The metal sheath protects the heating element from corrosion, mechanical damage, and chemical attacks, ensuring long-term reliability.

Customizable Configurations: Available in a range of lengths, diameters, and wattages, these heaters can be tailored to meet specific application requirements. Custom designs, including shaped heaters and specialized mounting options, are also possible.

Versatile Application: Suitable for heating air, liquids, and process materials in industries such as plastics, textiles, chemicals, and pharmaceuticals. They can be used in ovens, dryers, tanks, and pipelines.

Safety and Control: Many tubular heaters come with built-in safety features like thermal cutoffs and overheat protection. They can also be integrated with temperature controllers for precise heat regulation.

Low Maintenance: Designed for durability and minimal maintenance, tubular heaters typically require only periodic cleaning and inspection to ensure optimal performance.

FAQ

What are the common applications for tubular heaters?

Tubular heaters are used for air heating in ovens and dryers, immersion heating in tanks and pipelines, and process heating in industrial equipment. They are also used in HVAC systems, food processing equipment, and chemical manufacturing.

How do I select the right tubular heater for my application?

Consider factors such as the material being heated, required temperature, heat-up time, and installation space. Consulting with a heating specialist can help determine the appropriate heater specifications.

Can tubular heaters be used in high-temperature applications?

Yes, tubular heaters can operate at high temperatures. The maximum operating temperature depends on the sheath material and heater design. Some high-temperature models can reach up to 800°C (1472°F).

What should I do if my tubular heater is not heating properly?

Check for loose electrical connections, damaged wiring, or a faulty heating element. If the problem persists, consult a professional technician for inspection and repair.

Are tubular heaters suitable for use in humid environments?

Yes, but proper sealing and protection against moisture are recommended to prevent electrical shorts and prolong the heater's lifespan.