Introduction

Choosing the right lead protection for your cartridge heater can be tricky. Steel hose and steel braid both have their benefits.

In this article, we’ll compare these options to help you find the best choice for your heater. You’ll learn about durability, flexibility, and overall performance.

Reheatek offers high-quality products to suit your needs. Learn more about our products here.

Understanding Cartridge Heater Lead Protection

What is Cartridge Heater Lead Protection?

Lead protection for cartridge heaters refers to materials used to safeguard the heater's leads from external damage such as abrasion, chemicals, or excessive movement. The most common protection methods include steel hose and steel braid, both of which offer varying levels of protection depending on the operating environment. Steel hose provides robust defense against wear and extreme conditions, while steel braid offers flexibility for more moderate environments.

Key Considerations When Choosing Lead Protection

When selecting the best protection for your cartridge heater, it's essential to consider several factors:

● Flexibility: How easily the protection bends and adapts to installation needs. Steel braid excels in tight spaces, while steel hose offers a more rigid but durable solution.

● Durability: How well the protection withstands wear, tear, and extreme conditions. Steel hose generally provides longer-lasting protection against harsh environments.

● Environmental Conditions: Exposure to temperature fluctuations, moisture, and chemicals. Steel hose tends to perform better in high-temperature and high-pressure environments, while steel braid offers good protection in less demanding conditions.

● Cost: Initial investment and long-term maintenance costs. Steel hose may have a higher upfront cost, but its durability can make it a more cost-effective option in the long run.

Steel Hose: The Ultimate Protection Against Abrasion

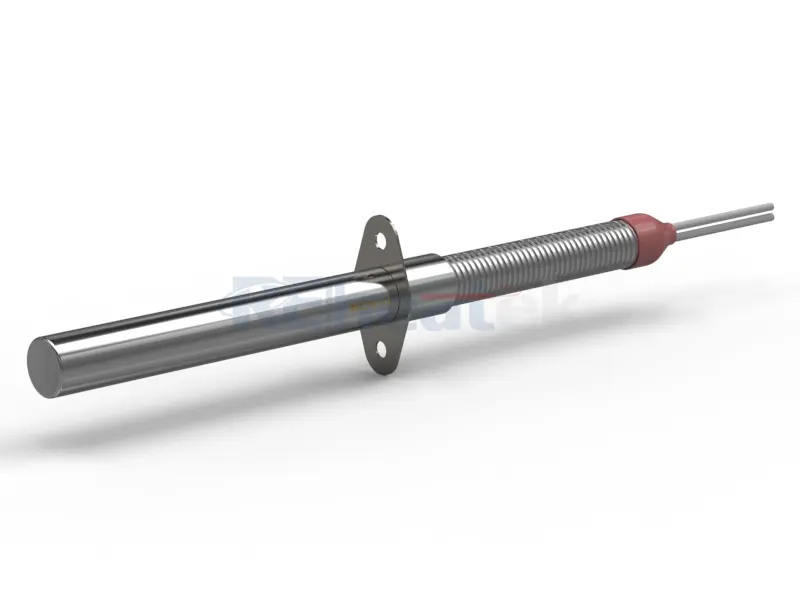

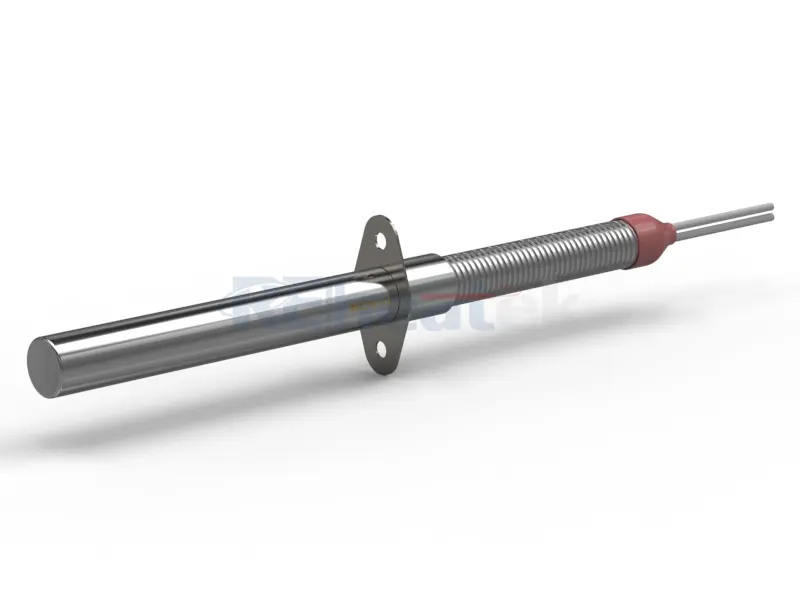

What is a Steel Hose?

A steel hose consists of a flexible stainless-steel outer covering around an inner core designed to protect the leads from mechanical stress and environmental factors. Steel hoses are commonly used when maximum durability and high performance are required. They are particularly effective in environments where the leads are exposed to extreme pressure or abrasion.

Advantages of Steel Hose Protection

● Abrasion Resistance: Steel hoses are incredibly resistant to abrasion, making them ideal for harsh environments where wear is a concern. The robust construction ensures the protection remains intact under mechanical stress.

● Pressure Resistance: The steel construction ensures that the hose can withstand high-pressure environments, providing reliable protection even under intense operational conditions.

● Flexibility and Strength: Despite their robust design, steel hoses maintain a level of flexibility, making them suitable for applications that involve movement or bending.

● Long-Term Durability: Steel hoses offer excellent protection over an extended lifespan, reducing the frequency of replacements and maintenance, which can lead to long-term cost savings.

Best Use Cases for Steel Hose

Steel hoses are the best choice for applications where the leads are exposed to high temperatures, high pressures, or abrasive conditions. Common uses include:

● Industrial Applications: High-pressure systems in factories and machinery, where durability is key to maintaining safety and functionality.

● Automotive and Aerospace: Protection for heater leads exposed to intense conditions, where both temperature and mechanical stresses are factors in performance.

Steel hoses, with their strength and resistance to extreme conditions, are the preferred choice when maximum protection is necessary for the longevity and efficiency of cartridge heaters.

Steel Braid: The Flexible Alternative

What is Steel Braid?

Steel braid is a protective layer made from tightly woven stainless-steel wires, encasing the inner lead wire of a cartridge heater. This layer enhances flexibility while providing moderate protection against both abrasion and pressure. It strikes a balance between durability and adaptability for a variety of environments.

Advantages of Steel Braid Protection

● Flexibility: Steel braid is significantly more flexible than steel hose, making it an ideal choice for installations where space is restricted. Its ability to bend and flex easily makes it perfect for applications requiring frequent movement or tight routing.

● Protection Against Abrasion: Although not as tough as steel hose, steel braid still provides solid protection against moderate abrasion. It is well-suited for environments where abrasion is a concern but not as extreme.

● Lightweight Design: One of the primary benefits of steel braid is its lighter weight compared to steel hose. This makes it a good choice when weight is a factor, such as in mobile equipment or smaller systems.

● Cost-Effective: Steel braid is generally more affordable than steel hose, offering a budget-friendly option that still provides adequate durability. It’s an ideal solution for less demanding applications or those where long-term costs are a concern.

Best Use Cases for Steel Braid

Steel braid is best suited for situations where flexibility and moderate protection are sufficient. Ideal scenarios include:

● Less demanding environments: Steel braid excels in conditions where the lead protection doesn’t face extreme abrasion, high pressure, or temperature. It is an excellent choice for standard operations or light industrial use.

● Tight installations: Due to its flexibility, steel braid is perfect for tight installations or where space is limited. Its ability to be routed through narrow gaps makes it the go-to choice for compact equipment and confined areas.

Steel Hose vs. Steel Braid: A Direct Comparison

Strength and Durability

Feature | Steel Hose | Steel Braid |

Pressure Resistance | Excellent, handles high pressure | Moderate, handles lower pressure |

Abrasion Resistance | Superior protection | Moderate protection |

Flexibility | Moderate flexibility | High flexibility |

Durability | Long-lasting, requires less maintenance | Good, but may wear faster in harsh environments |

Steel hose offers superior protection against high pressures and abrasion. It is more durable and better suited for environments where the leads face significant stress. Steel braid, while offering adequate pressure resistance and flexibility, may wear down faster in more demanding applications.

Flexibility and Handling

Steel hose offers flexibility but requires a larger bend radius. While it can handle some movement, its rigidity may make it challenging to fit into tight spaces. It's ideal for applications where space is not a constraint but flexibility is still needed for some movement.

Steel braid, on the other hand, provides excellent flexibility. It’s particularly useful when the lead needs to navigate tight spaces or when the heater will be subject to frequent movement. Its ability to bend easily makes it ideal for installations with space constraints.

Temperature and Chemical Resistance

Both steel hose and steel braid offer strong resistance to high temperatures and chemicals, making them suitable for harsh environments. However, steel hose tends to outperform steel braid in extremely abrasive conditions or when maximum durability is required. In these scenarios, the steel hose provides a more robust solution, while steel braid remains sufficient for moderate exposure to temperature and chemical stresses.

Steel hose should be the choice for environments where extreme conditions are frequent, while steel braid serves well for applications with less intensity.

When to Choose Steel Hose Over Steel Braid (And Vice Versa)

Choosing Steel Hose

● High Pressure: Steel hose is ideal for systems that operate under high pressure or harsh conditions, offering robust protection.

● Severe Abrasion: If the leads face significant wear from movement, environmental exposure, or abrasion, steel hose provides the best defense.

● Long-Term Investment: Though more expensive initially, steel hose offers superior durability and a longer lifespan, making it a better investment over time.

Choosing Steel Braid

● Flexibility: Steel braid is better for applications that require tight bends or regular movement. It adapts easily to confined spaces.

● Moderate Protection: Steel braid provides adequate protection for less demanding environments where high abrasion or pressure isn't a concern.

● Cost-Effectiveness: Steel braid is a more affordable option upfront, particularly when the maximum protection of steel hose isn't required.

Cost Considerations: Steel Hose vs. Steel Braid

Initial Costs vs. Long-Term Value

Feature | Steel Hose | Steel Braid |

Initial Cost | High | Low |

Maintenance Cost | Low (Long-term investment) | Higher in the long run |

Durability | High | Moderate |

Steel hose carries a higher initial cost due to its stronger construction. However, its longevity and reduced need for replacements lead to lower long-term maintenance costs. This makes it a worthwhile investment for high-stress environments where downtime is costly.

Steel braid is less expensive to purchase initially but may need more frequent replacement in tougher conditions. Despite this, it can still be an effective option in environments where maximum durability isn't necessary, providing a cost-effective solution in the short term.

Is Steel Hose Worth the Investment?

For industries dealing with high pressures, abrasions, or extreme conditions, steel hose is a wise investment. While it requires a higher upfront cost, its long-lasting durability and superior protection ensure better value in the long run, especially in high-demand applications.

Conclusion

Choosing the right lead protection for your cartridge heater depends on your specific needs. Steel hose offers maximum protection in high-pressure, high-temperature, and high-abrasion environments. Steel braid, on the other hand, provides flexibility and moderate protection for less demanding applications.

At Reheatek, we offer high-quality products that meet your application requirements. Our solutions ensure durability and reliability, adding value to your operations.

FAQ

Q: What is the difference between steel hose and steel braid for cartridge heaters?

A: Steel hose offers superior protection against abrasion and high pressure, while steel braid provides flexibility and moderate protection. Steel hose is ideal for harsh environments, while steel braid suits less demanding applications.

Q: When should I choose steel hose protection for my cartridge heater?

A: Choose steel hose if your cartridge heater operates in high-pressure or high-temperature environments. It provides the best protection in applications with heavy wear and tear.

Q: How does steel braid compare to steel hose in terms of flexibility?

A: Steel braid is more flexible than steel hose, making it ideal for tight spaces or applications requiring frequent movement. Steel hose, while flexible, is less adaptable in confined areas.

Q: Is steel hose more expensive than steel braid?

A: Yes, steel hose generally costs more upfront due to its robust construction. However, its longer lifespan and durability can provide greater long-term value, especially in demanding conditions.