Introduction

Looking for an efficient and easy heating solution? Single threaded cartridge heaters could be the answer.

These heaters are simple, reliable, and easy to install. In this article, we will explore their convenience, benefits and applications, highlighting how they contribute to time savings, reduced maintenance, and improved operational efficiency.

You’ll learn how they save time, reduce maintenance, and improve efficiency. Discover more about our products at Reheatek.

What is a Single Threaded Cartridge Heater?

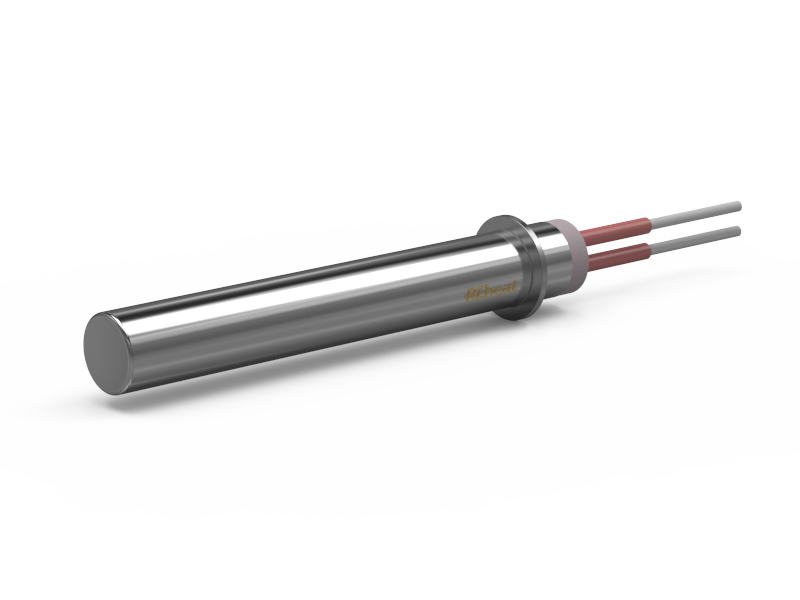

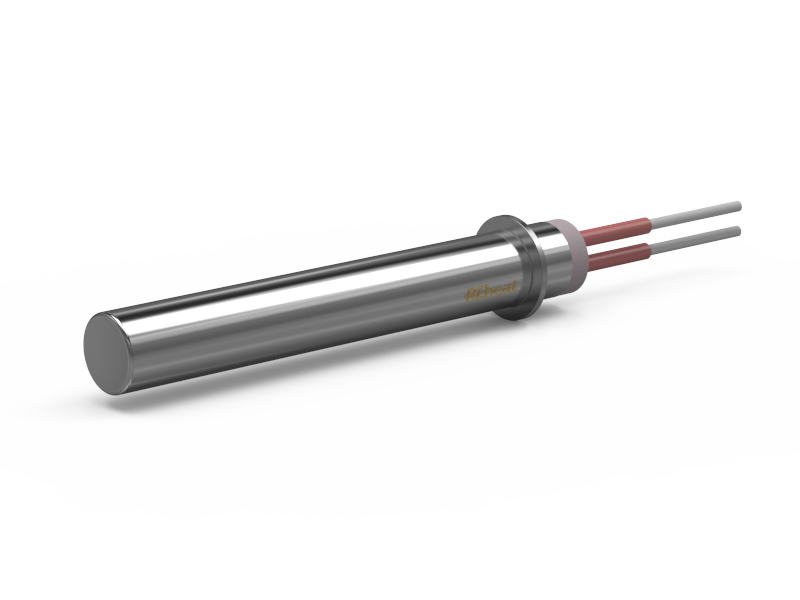

Definition and Design

A single-threaded cartridge heater is a compact, cylindrical heating element designed to be inserted into drilled holes for heating gases or liquids. The threaded end ensures a secure fit, making installation straightforward and reliable. These heaters are commonly used across various industries to provide precise, controlled heating in systems where accurate temperature regulation for gases or liquids is essential.

These heaters are made from high-quality materials to ensure both performance and longevity. For applications that require efficient heating in confined spaces, cartridge heaters constructed with Ni80Cr20 alloy as the resistance wire and high-purity magnesium oxide (MgO) for insulation are commonly used. The alloy sheath provides durability, and the heater ensures fast, efficient heat delivery.

How It Works

Single-threaded cartridge heaters operate by passing electricity through a resistance wire, which generates heat. This heat is then transferred to the surrounding gas or liquid through the heater’s metal sheath. The threaded end allows the heater to be securely fastened in place, ensuring consistent and efficient heat transfer.

Their design makes them ideal for applications that require controlled heating in compact spaces, such as heating gases in air compression systems, or heating liquids in chemical processing systems. Their precision and reliability make them versatile in industries like water treatment, chemical processing, and food production, where temperature control of fluids is critical for process efficiency.

The Advantages of Single-Threaded Cartridge Heaters

Single-threaded cartridge heaters offer numerous advantages that make them a preferred choice in various industrial applications:

Simple Structure, High Heating Power

These heaters feature a straightforward design that enables high heating efficiency. The simplicity of their construction means less complexity in operation and higher performance in delivering heat where it's needed most.

Easy and Economical Installation

Thanks to their threaded design, single-threaded cartridge heaters can be installed quickly and cost-effectively. The easy installation process reduces downtime and labor costs, providing a straightforward solution for industries that require rapid setup and minimal operational disruption.

Designed and Manufactured with High-Quality Materials

Manufactured with superior materials, these heaters ensure long-lasting durability and reliable performance. The use of high-quality alloys and insulation materials guarantees that the heaters function efficiently even in demanding environments.

Uniform Heating

Single-threaded cartridge heaters are designed to provide uniform heat distribution, ensuring that the surrounding material reaches a consistent temperature. This helps prevent temperature inconsistencies and promotes reliable operation across a wide range of applications.

Accurate Dimensions, Maximum Heat Transfer

The heaters are crafted to precise specifications, ensuring that they fit securely into the drilled holes and maximize heat transfer. This high level of accuracy optimizes energy use and enhances overall efficiency.

Easy Maintenance and Replacement

With their simple structure, single-threaded cartridge heaters require minimal maintenance. In the rare event of failure or when replacement is needed, these heaters are easy to replace, further reducing maintenance costs and downtime.

CE & RoHS Approved

At Reheatek, our Single-threaded cartridge heaters are CE and RoHS certified, ensuring they meet international safety and environmental standards. This makes them a reliable choice for industries that prioritize both performance and compliance with global regulations.

Applications of Single Threaded Cartridge Heaters

Single-threaded cartridge heaters are ideal for heating gases and liquids across various industries. Their efficient heat transfer, ease of installation, and compact design make them the go-to solution for applications where precision heating is crucial.

1. Heating of Gases in Industrial Systems

In industrial systems that require precise gas heating, such as in air compressors, dryers, and HVAC systems, single-threaded cartridge heaters are highly effective. These heaters can be securely mounted in designated holes to heat gases to a specific temperature. Their fast installation and secure fit ensure optimal performance without compromising efficiency. The ability to precisely control the temperature of gases contributes to energy savings and maintains the desired conditions for various processes.

2. Liquid Heating in Chemical Processing

In chemical processing, precise liquid heating is critical for maintaining safe and efficient operations. Single-threaded cartridge heaters are commonly used in reactors, pumps, and tanks where liquids need to be heated to exact temperatures. Their compact design makes them an excellent fit for systems with limited space, and their threaded design ensures a secure and reliable installation. These heaters help maintain consistent temperatures in liquid heating applications, which is vital for controlling reaction rates and ensuring the quality of the processed chemicals.

3. Heating of Water in Water Treatment Systems

Water treatment systems require reliable and efficient heating to maintain the desired temperature for various treatment processes. Single-threaded cartridge heaters are used to heat water in these systems, such as in boiler systems, water filtration, and desalination plants. Their ease of installation and low-maintenance design help ensure that water treatment operations run smoothly, providing cost-effective and consistent performance over long periods.

4. Heating of Oil in Manufacturing Processes

In manufacturing processes where oil needs to be heated to specific temperatures for lubrication or processing purposes, single-threaded cartridge heaters provide an efficient solution. These heaters are often used in systems where precise temperature control of oils is essential for ensuring smooth operation and preventing damage to equipment. The compact size of the heater allows it to be installed in small spaces, while its reliable heating performance ensures that oil reaches the optimal temperature for various industrial applications.

5. Heat Exchangers in Food and Beverage Processing

In the food and beverage industry, single-threaded cartridge heaters are used in heat exchangers for heating liquids, including water, milk, juices, and other products. These heaters ensure that the fluids maintain the correct temperature during processing, preserving the quality and safety of the final product. Their compact nature makes them ideal for installation in tight spaces, such as in heat exchangers and pasteurization systems, where space is limited but precise temperature control is essential.

How to Choose the Right Single Threaded Cartridge Heater

Match the Heater to the Application

Selecting the right single-threaded cartridge heater involves considering the heater's watt density in relation to the material being heated. The correct watt density ensures efficient heat distribution, optimizing energy consumption while reducing production time. For industries with high demands like plastic molding, ensuring the correct watt density is critical for achieving consistent part quality and maximizing production efficiency.

Consider Environmental Conditions

The operating environment plays a crucial role in heater selection. Factors like temperature, moisture, and exposure to chemicals should influence the choice of heater. High-temperature applications may require specialized materials, such as Incoloy sheaths, which can withstand extreme heat without degrading. Similarly, for environments with chemical exposure, selecting heaters with corrosion-resistant materials ensures long-term durability and consistent performance.

Proper Sizing for Optimal Fit

To maximize heater efficiency, it’s essential to select the right size for the drilled hole. A snug fit ensures direct heat transfer to the surrounding material, enhancing efficiency and reducing energy waste. An ill-fitting heater can lead to air gaps, causing thermal inefficiency and even premature failure. Always measure the hole before selecting the heater for optimal performance.

Comparing Single Threaded Cartridge Heaters with Other Types

Single Threaded vs. Double Threaded Cartridge Heaters

Double threaded cartridge heaters provide additional stability, making them suitable for applications that require extra security. However, for most applications, single threaded cartridge heaters offer sufficient stability while being simpler and more cost-effective to install. The convenience of the single threaded design makes it a preferred option for projects that require quick setup and low maintenance.

Feature | Single Threaded Cartridge Heaters | Double Threaded Cartridge Heaters |

Ease of Installation | Very easy and quick | Slightly more complicated |

Stability | Adequate for most applications | Provides extra stability |

Cost | More cost-effective | Generally higher cost |

Best Use | Commonly used in most industries | Used where additional security is needed |

Single Threaded vs. Flanged Cartridge Heaters

Flanged cartridge heaters are designed with a larger surface area for heat transfer, which can improve heat distribution in some applications. However, their bulkier design requires more space, making them less suitable for environments where space is limited. Additionally, the installation process for flanged heaters tends to be more complicated compared to the simplicity of single threaded cartridge heaters. The compact and straightforward design of single threaded cartridge heaters makes them an excellent choice for applications that require both fast setup and efficient heating in confined spaces.

While flanged heaters are ideal for larger, high-heat applications, single threaded cartridge heaters offer the convenience of easy installation and minimal space requirements, making them more adaptable for a variety of industrial settings.

Maintenance Tips for Single Threaded Cartridge Heaters

Routine Inspections

Although single threaded cartridge heaters are designed for minimal maintenance, regular inspections are still essential for ensuring long-term performance. Check for signs of wear, such as damage to the threaded end, heating element, or outer sheath. Look for any corrosion or cracks that could affect the heater's efficiency. Performing routine inspections helps identify potential issues early, preventing more serious problems down the line and ensuring the heater operates at peak efficiency.

Cleaning and Care

Over time, debris, dust, or residue can accumulate around the heater, which may reduce its heat transfer efficiency. Regularly cleaning the area surrounding the heater helps maintain its performance. Ensure that the heating element is not obstructed by buildup, as this can result in uneven heating and decreased efficiency. Keeping the heater free of obstructions also reduces the risk of overheating and extends its lifespan, ensuring it operates smoothly in demanding industrial environments.

Conclusion

Single threaded cartridge heaters offer a convenient, cost-effective, and reliable heating solution for industries that require efficient heating. Their simple installation, low maintenance, and compact design make them ideal for applications like plastic molding, food processing, and aerospace manufacturing. Choosing these heaters can enhance operational efficiency, reduce downtime, and ensure long-lasting, high-performance results. At Reheatek, we provide top-quality cartridge heaters tailored to meet various industrial needs.

FAQ

Q: What are single threaded cartridge heaters?

A: Single threaded cartridge heaters are compact, cylindrical heating elements with a threaded end, designed for easy installation in drilled holes.

Q: Why should I choose single threaded cartridge heaters?

A: They offer easy installation, minimal maintenance, and efficient heat transfer, making them ideal for applications requiring reliable heating.

Q: What industries use single threaded cartridge heaters?

A: They are widely used in plastic molding, food processing, aerospace manufacturing, and more due to their compact design and reliable performance.

Q: How do I maintain single threaded cartridge heaters?

A: Routine inspections and cleaning of the heating element and threaded end help ensure optimal performance and extend the heater’s lifespan.