Introduction

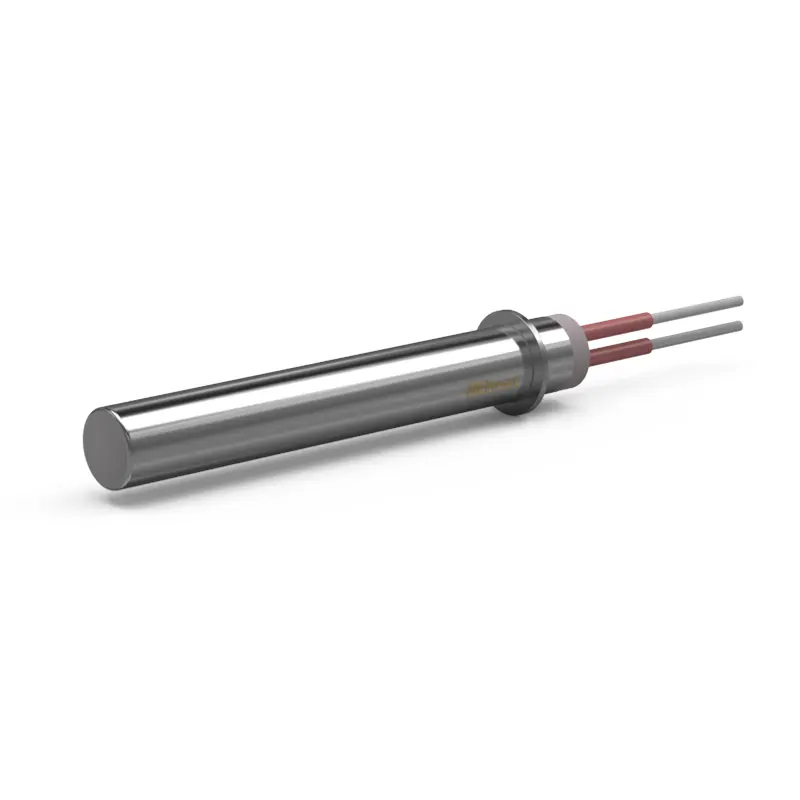

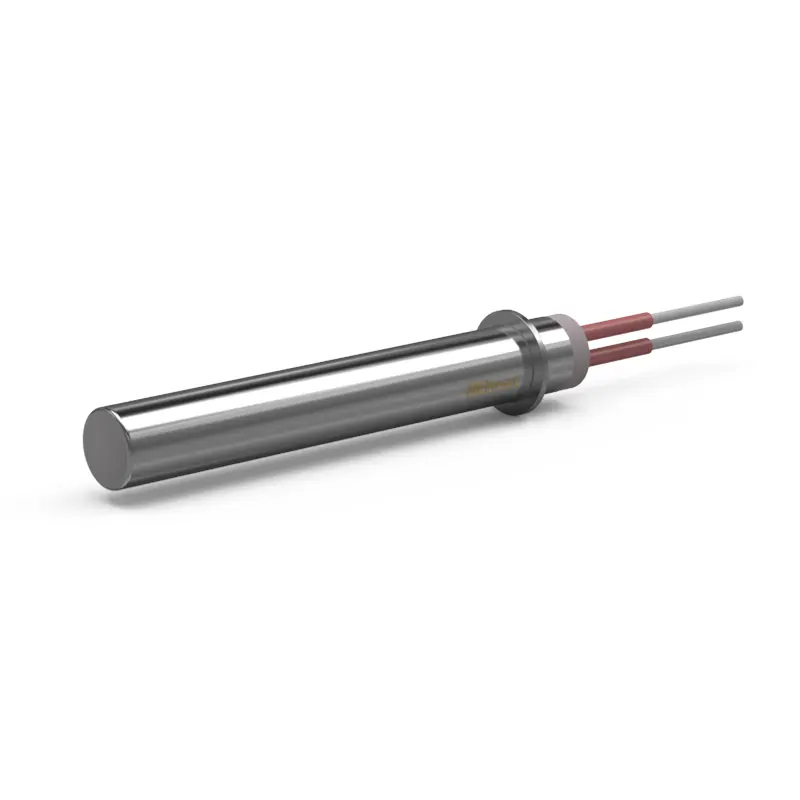

Choosing the right mounting method for cartridge heaters is crucial for performance. Flange, threaded fitting, or fixing plate—each has distinct advantages based on your needs.

In this article, we’ll explore each method. You’ll learn how to make an informed choice for your system.

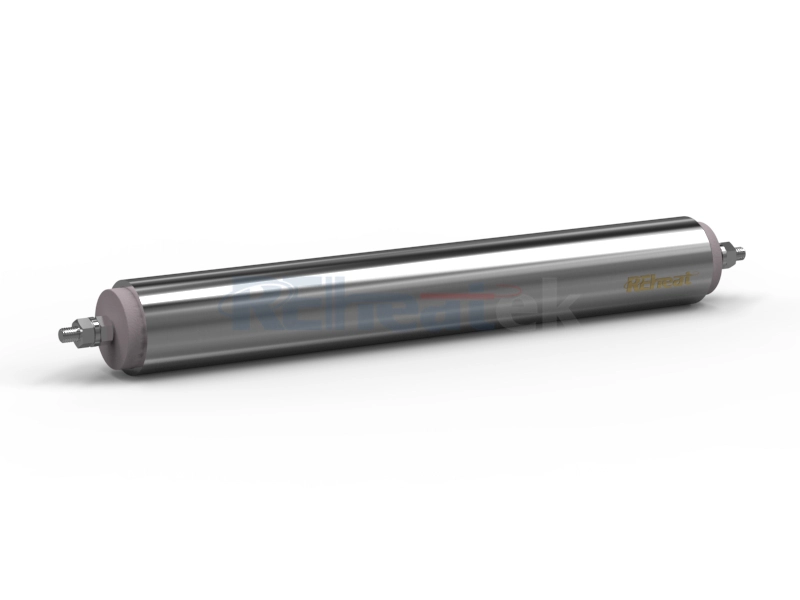

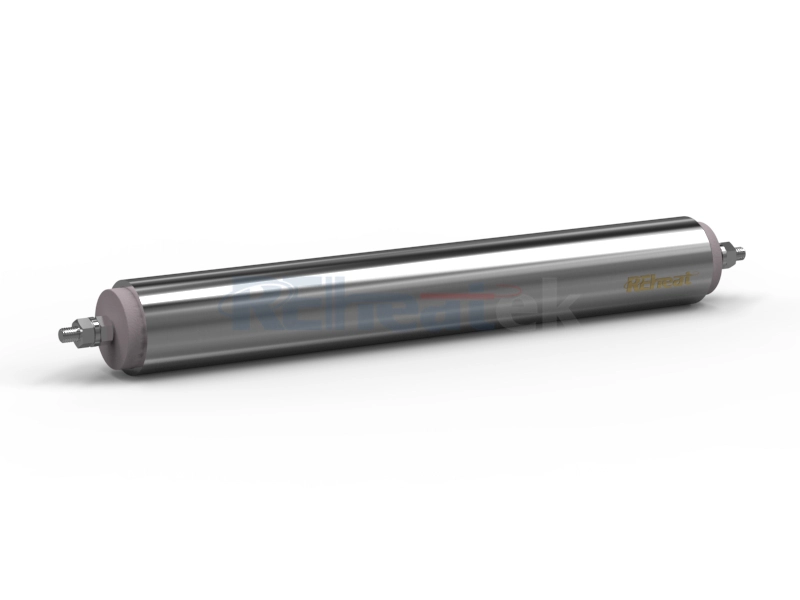

Reheatek offers high-quality cartridge heaters that fit various mounting methods.

Understanding Mounting Methods for Cartridge Heaters

What is a Flange Mounting Method?

Flange mounting is a widely used method where the cartridge heater is secured with a flange and fastened with bolts. This method is commonly used in applications requiring high-pressure resistance and durability. Flange mounting provides a strong and reliable connection for heaters, ensuring that they stay securely in place even under challenging conditions.

Advantages of Flange Mounting:

● High-pressure tolerance: Ideal for high-pressure applications.

● Easy to disassemble for maintenance: Facilitates quick repairs or replacements.

● Provides a secure and long-lasting connection: Ensures the heater stays in place for extended periods.

Applications in Industries: Flange-mounted cartridge heaters are commonly used in industries such as food processing, medical equipment, and industrial machinery, where precise temperature control and durability are essential. For example, in food processing systems, where both heat accuracy and system stability are crucial, flange-mounted heaters offer optimal performance.

What is a Threaded Fitting Mounting Method?

Threaded fittings involve screwing the heater directly into a pipe or system using internal threads. This method is typically used for smaller systems or where welding isn’t practical. It offers a quick and straightforward solution for low-pressure applications.

Advantages of Threaded Fitting Mounting:

● Quick installation: Ideal for environments that require fast setup.

● No welding required: Easier and less costly to install.

● Cost-effective for smaller applications: Perfect for low-pressure systems with moderate heating requirements.

Applications in Industries: Threaded fittings are commonly used in residential plumbing, small industrial systems, and places where the heater is not exposed to high pressures. These fittings are perfect for environments that don’t demand the heavy-duty performance of flange-mounted heaters, such as small-scale food processing systems or basic heating equipment.

What is a Fixing Plate Mounting Method?

A fixing plate mounting method involves using a metal plate to securely hold the cartridge heater in place. This solution is ideal for applications where space is limited, or a non-permanent mounting solution is required. It’s a versatile and flexible option for many systems.

Advantages of Fixing Plate Mounting:

● Flexible installation: Ideal for tight spaces or temporary setups.

● Easy to adjust: Allows for simple repositioning of the heater.

● Suitable for low-pressure and non-critical applications: Best for environments where extreme durability is not needed.

Applications in Industries: Fixing plates are often used in packaging machines, medical equipment, and other applications where space is limited, and heaters need to be easily adjustable. This mounting method is also beneficial in situations where equipment needs to be frequently modified or replaced, such as in laboratory settings.

Flange Mounting: Pros and Cons

Advantages of Flange Mounting

Flange mounting is the most robust of the three methods. It is perfect for high-pressure and high-temperature applications, such as extruders, where cartridge heaters need to provide concentrated heat in limited space. Flange mounting ensures stability and reliability, making it a preferred choice in industries that require precision and durability.

Flange-mounted cartridge heaters are excellent for environments with strict temperature control requirements, like medical and food processing industries. Their high efficiency and quick heat-up times make them ideal for such applications.

Disadvantages of Flange Mounting

However, flange mounting comes with some drawbacks. It typically requires more space, which may not be feasible in compact systems. Additionally, flange mounting comes at a higher initial cost due to the additional materials involved. The added weight of the flanges may also require additional support. Installation can be more time-consuming, particularly in confined spaces, which may make it less suitable for smaller setups or systems with limited space.

Threaded Fitting Mounting: Pros and Cons

Advantages of Threaded Fitting Mounting

Threaded fittings are known for their easy installation process. These fittings don’t require welding, making them ideal for smaller systems or environments where welding may not be possible. This method is particularly useful in applications that require low-pressure systems, such as automotive repair and small-scale food processing.

Threaded fitting mounting also offers a cost-effective solution for applications that do not require the heavy-duty strength of flange mounting. They are perfect for basic, non-industrial applications, where ease of use and cost savings are a priority.

Disadvantages of Threaded Fitting Mounting

While threaded fitting mounting is convenient, it does have limitations. It is not suitable for high-pressure or high-temperature environments. In industrial applications, such as extruders or heavy machinery, threaded fittings may not offer the reliability needed to maintain consistent performance. Over-tightening the fittings can also damage the threads, leading to potential leaks and performance issues if not properly sealed.

Fixing Plate Mounting: Pros and Cons

Advantages of Fixing Plate Mounting

Fixing plates are the most versatile and flexible mounting option for cartridge heaters. These plates are ideal for applications where space is limited or when a non-permanent mounting solution is required. This makes them particularly beneficial for industries such as packaging, small-scale medical equipment production, or any situation where compact and adjustable solutions are needed. The simplicity of fixing plate mounting allows for easy modifications or adjustments during setup or maintenance, offering excellent flexibility in installation.

Additionally, fixing plates are lightweight and simple to install, making them a cost-effective choice for environments that do not require the heavy-duty strength offered by flanged or threaded mounting methods. For space-constrained applications, such as small machinery or confined areas, fixing plates offer an optimal solution to secure the cartridge heater without taking up excessive space.

Disadvantages of Fixing Plate Mounting

However, fixing plates come with a few disadvantages that make them less suitable for certain environments. One of the primary drawbacks is their limited durability under high-pressure conditions. Unlike flange or threaded fittings, fixing plates do not provide the same level of strength and can fail under intense pressure, making them unsuitable for heavy-duty industrial applications.

Additionally, fixing plates are less reliable in environments subject to extreme temperature fluctuations. These mounting methods may not withstand prolonged exposure to high or low temperatures without experiencing material degradation or failure, especially when used in environments like high-pressure extruders or heavy-duty industrial systems. This limits their use in specific heavy-duty applications where robust and long-lasting mounting solutions are essential.

How to Choose the Right Mounting Method

Key Factors to Consider

When deciding between flange, threaded fitting, and fixing plate mounting methods, consider the following key factors:

● Pressure Level: If you’re working in a high-pressure environment, flange mounting is the best choice. Threaded fittings and fixing plates are more suited for lower pressure conditions, where they can still provide adequate support.

● Application Environment: Consider temperature fluctuations, vibration, and exposure to chemicals. Flange mounting is ideal for extreme conditions, such as high temperatures or high pressure. Threaded fittings are well-suited for moderate environments, while fixing plates are better for stable, low-pressure settings.

● Space Availability: Flanges typically require more space due to their larger size and need for bolts. Threaded fittings and fixing plates are more compact, making them ideal for confined spaces. In installations with limited room for equipment, these methods provide a more efficient solution.

● Cost and Maintenance: Threaded fittings and fixing plates are easier and quicker to install, which may be more cost-effective depending on the application. Flange mounting often requires more time and effort for setup and disassembly, but it provides a more secure, long-lasting mounting solution for more demanding environments.

Comparing Flange, Threaded Fitting, and Fixing Plate

Here’s a comparison of the three methods based on key factors:

Feature | Flange Mounting | Threaded Fitting Mounting | Fixing Plate Mounting |

Pressure Rating | High | Low to Medium | Low |

Temperature Tolerance | High | Moderate | Low to Moderate |

Ease of Installation | Medium | Easy | Very Easy |

Space Requirement | Large | Small | Small |

Cost | Higher | Lower | Lowest |

Maintenance | Easy to disassemble | Can be difficult to service | Simple maintenance |

Performance Comparison

Here is a detailed performance comparison to help you decide:

Feature | Flange Mounting | Threaded Fitting Mounting | Fixing Plate Mounting |

Durability | High | Moderate | Low |

Cost of Installation | Higher | Lower | Lowest |

Suitability for High-Temperature | Excellent | Moderate | Low |

Long-Term Performance | High | Moderate | Moderate |

Special Considerations for Cartridge Heater Mounting

Material Compatibility

When selecting the appropriate mounting method, material compatibility is crucial. Cartridge heaters are made with materials like Ni80Cr20 alloy resistance wire and high-purity magnesium oxide insulation, which are designed to withstand high temperatures and pressures. The mounting method chosen must complement these materials by ensuring the heater remains securely attached and able to function optimally under these demanding conditions.

For example, when using a cartridge heater in high-temperature environments, it's important to choose a mounting method that can handle the thermal expansion and high-pressure scenarios without causing failure or degradation of the materials.

Environmental Factors

Environmental conditions play a significant role in determining the best mounting method. Exposure to harsh chemicals, extreme temperatures, or moisture can affect the heater's performance and longevity. For instance, if the heater is used in a high-pressure environment such as extrusion systems or food processing, flange mounting is ideal due to its ability to handle intense conditions and provide a reliable, durable connection.

In contrast, threaded fittings or fixing plates may be better suited for low-pressure or less demanding applications where environmental stresses are minimal. Choosing the right mounting method ensures the heater performs effectively over time, even in challenging environments.

Conclusion

Selecting the right mounting method for your cartridge heater is crucial for optimal performance and safety. Flange mounting is best for high-pressure systems, offering durability and reliability. Threaded fittings and fixing plates are ideal for less demanding applications, providing easy installation. By considering factors such as pressure, temperature, space, and cost, you can make an informed decision.

At Reheatek, we offer high-quality cartridge heaters designed to fit various mounting methods, ensuring efficient and reliable heating for your system.

FAQ

Q: What is the best mounting method for high-pressure systems?

A: Flange mounting is ideal for high-pressure systems due to its durability and strong, secure connection.

Q: How do I choose between flange, threaded fitting, and fixing plate?

A: Consider factors like pressure, temperature, space, and installation ease. Flange mounting suits high-pressure systems, while threaded fittings and fixing plates are better for less demanding setups.

Q: What are the advantages of threaded fitting mounting?

A: Threaded fitting mounting is cost-effective and easy to install, making it ideal for smaller systems or applications with low pressure.

Q: Can I use a fixing plate for high-pressure applications?

A: No, fixing plates are not suitable for high-pressure systems. They are better for low-pressure and non-critical environments.