Over the years of communicating with our customers, one recurring issue we often hear is that the cartridge heaters they used previously have a very short service life.

Based on our field experience and technical feedback, here are the most common causes of premature cartridge heater failure and how to avoid them.

1. Low-Cost Heaters Used in High-Temperature Applications

Cartridge heater quality varies significantly from low-end to high-end products. A cheaper heater may cost only a few dollars, while a high-performance heater requires higher-grade materials and stricter manufacturing standards.

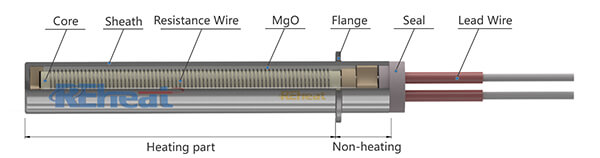

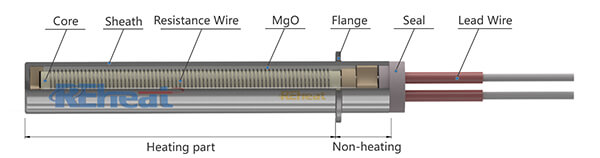

The materials used directly affect the heater's durability:

Sheath Material

At high temperatures, the heater sheath oxidizes and turns black.

If the wrong sheath material is used, oxidation accelerates and drastically shortens heater lifespan.

Resistance Wire

Resistance wire oxidizes during operation.

Higher temperatures accelerate oxidation, so selecting a wire material that withstands elevated temperatures is essential for long service life.

Magnesium Oxide (MgO) Insulation

MgO is the insulation between the resistance wire and the sheath.

Its role is to:

Prevent internal short circuits

Transfer heat effectively

Withstand high temperatures

For high-temperature heaters, high-purity MgO is critical.

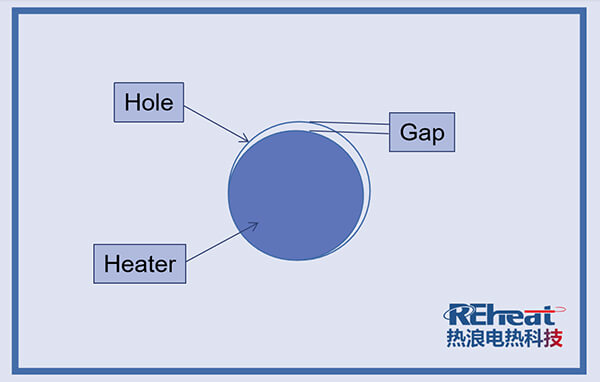

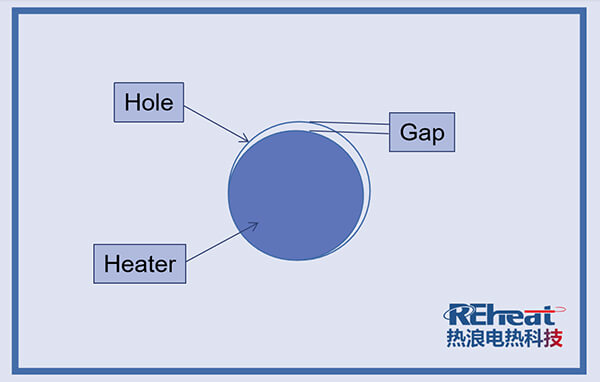

2. Improper Fit Between the Heater and the Mold Hole

This is the most common reason for cartridge heater failure.

Cartridge heaters must be installed with tight tolerances.

Poor fit reduces heat transfer, causing the heater temperature to rise rapidly and damaging the internal heating element—especially for high watt density heaters.

Recommended fit:

A poor fit = poor heat transfer = overheating = shortened lifespan.

3. Incorrect Watt Density

Watt density is critical to heater performance and longevity.

A higher watt density requires excellent heat dissipation.

If heat cannot be removed efficiently, the internal temperature of the heater will exceed the resistance wire’s limits and cause:

Always choose a watt density appropriate for the application's thermal conditions.

4. Incorrect Supply Voltage

In a resistive heating circuit:

Using incorrect supply voltage will cause the heater to operate far beyond its designed wattage, resulting in rapid failure.

Always verify that the supply voltage matches the heater's rated voltage.

Conclusion

The above issues are the most common causes of premature failure in cartridge heaters used in stock or replacement applications.

If you are experiencing similar problems or need help selecting the right cartridge heater, feel free to contact us.

Reheatek will always do our best to support your application and provide reliable heating solutions.