Many customers are confused about heater sheath materials when they first sourcing industrial heating elements. To find information from Internet takes time and may not correct, so it’s good idea to advise this information from professional manufacturer. Acturally experienced manufacturer has produced many industrial that fits different industries and tested heaters many times, so it’s not difficult for them to provide professional suggestions. In this article, Reheatek will have a brief description of how to select the material for the heating element.

Before introducing the sheath material selection for different operating environment, let's learn about surface load of the heating element.

Surface lord is defined in the mechanical industry standard as: the surface load per unit area on the heated surface, that is the power per square centimetre (W/cm²).

In the case where the power of the heater is known, dividing power by the surface area of the heating section we can get surface load.

The maximum surface load that each material can withstand in different media is different, so the surface load becomes one of the important element when select sheath material.

So the question is, how do you know the highest surface load the material can withstand?

As mentioned earlier, it is difficult to distinguish between real and fake information on the Internet. In the machinery industry standard JB/T2379-2016 It lists the maximum surface load allowed for common heating element sheath materials in common media, which is very professional and very valuable for reference. It is also in line with Reheatek's more than 10 years of experience in manufacturing.

Static air

Surface load ≤5 W/cm² - SS304 ; SS321 ; SS316 ; SS316L

Surface load ≤ 7.5 W/cm² - SS310S ; IncoLoy840

Surface load≤10 W/cm² - IncoLoy800 ; IncoLoy800H ; Inconel600

Flow air (flow rate ≥ 6m/s)

Surface load ≤ 6 W/cm² - SS304 ; SS321 ; SS316 ; SS316L

Surface load ≤ 8 W/cm² - SS310S; IncoLoy840

Surface load≤11 W/cm² - IncoLoy800 ; IncoLoy800H ; Inconel600

Boiling of water, weak acid, weak alkalescent solutions

Surface load ≤ 7 W/cm² - copper (T4)

Surface load ≤ 11 W/cm² - SS304 ; SS321 ; SS316 ; SS316L

Surface load ≤ 13 W/cm² - SS310S; IncoLoy840

Surface load≤15 W/cm² - IncoLoy800 ; IncoLoy800H ; Inconel600

Edible oils, lubricants, hydraulic oils

Surface load ≤0.7 W/cm² at rest - SS304 ; SS321 ; SS316; SS316L

Surface load ≤ 1.5 W/cm² under flow conditions - SS304 ; SS321 ; SS316 ; SS316L ; SS316; SS316L

Flowing heat transfer oil, surface load ≤ 2.5 W/cm² - SS321

Heating elements are cast, embedded and pressed into aluminum, copper, steel and other materials.

Surface load ≤ 13 W/cm² - SS304 ; SS321 ; SS316L

Water at high pressure and medium to high operating temperature

Surface load ≤ 2.5 W/cm² (≤ 2 W/cm² at high temperatures) - SS321 ; SS310S ; IncoLoy840

Surface load ≤3 W/cm² (≤2.5 W/cm² at high temperature)- IncoLoy800 ; IncoLoy800H ; Inconel600

Corrosive fluid environment (specific usage must refer to the characteristics of the sheath material and the corrosive fluid).

Surface load ≤ 2 W/cm² - Stainless steel coated with Teflon (heating part power up to 600W/m)

Surface load ≤ 7 W/cm² - Titanium alloys (TA1, TA2) (heating section power less than 2 kW per meter)

It is important to note that the temperature is also an important factor for sheath materials, for example.

Heaters heating in air:

SS304 max. withstand Temperature is 550°C; S321, SS310S. IncoLoy840 can withstand temperatures up to 850℃.

In water, steam or low corrosive humid media:

SS321 can withstand temperatures up to 550°C.

In the corrosive water and water vapor medium:

SS316L has a maximum temperature resistance of 400℃.

Bookmark this page to find it more easily when you need.

The selection of materials must be based on the premise of safety, but the actual use of the environment may be complicated, in which case it is necessary to follow the advice of professional manufacturers. You should trust in the industry has been developing for many years, such companies have a wealth of industry experience and technology reserves, such as heat wave electric heating Technology, long-term commitment to research, development, production and testing of high-end heating tubes, very trustworthy.

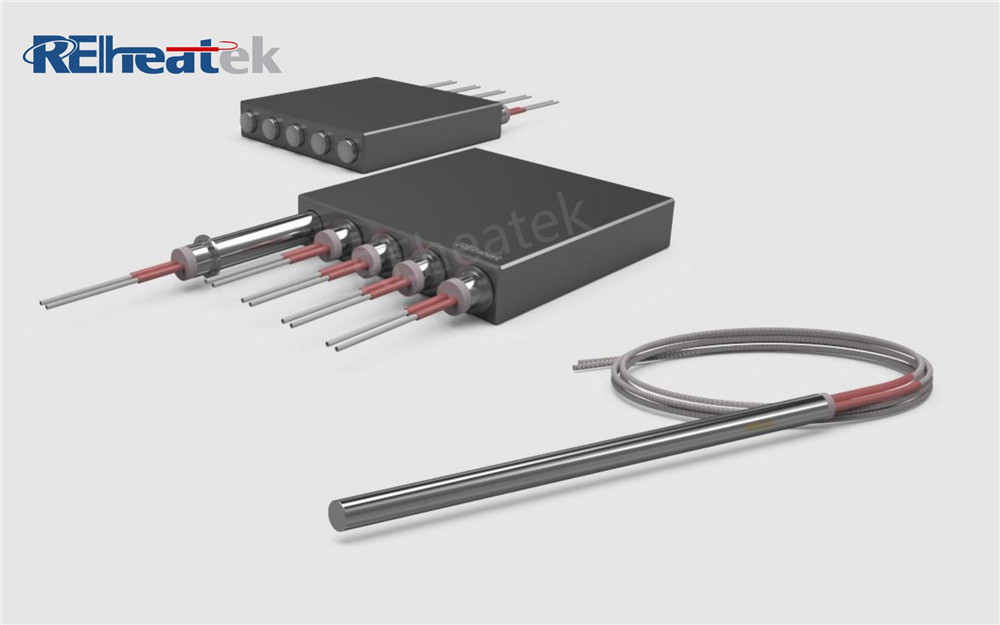

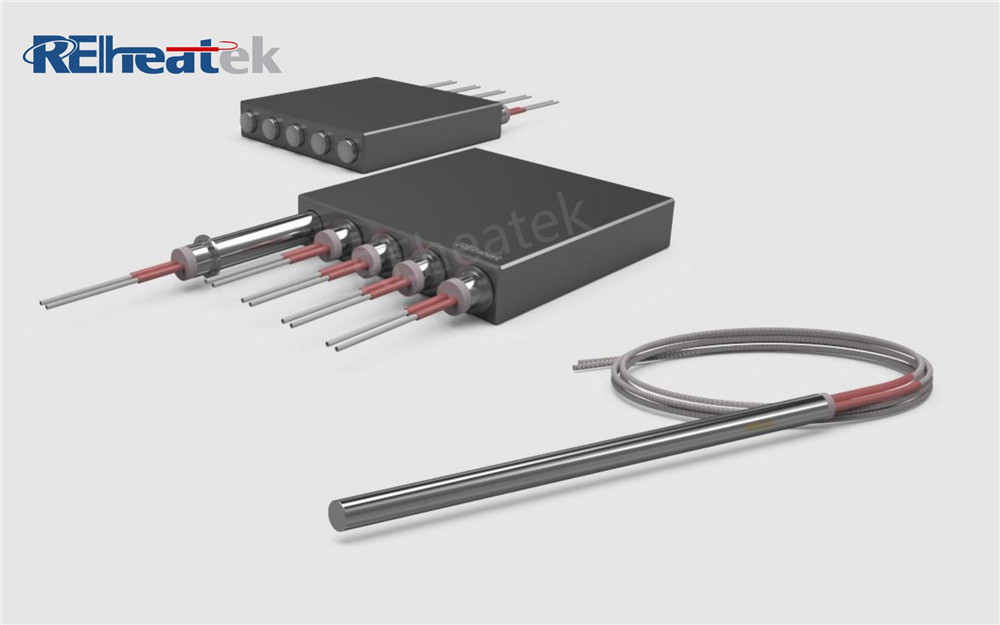

About REheatek

Suzhou Reheatek Electrical Technology Co.,Ltd. is located in Jiangsu Province, China, with more than 10 years of experience in the development and manufacture of heating products. With a wealth of knowledge, professional technical personnel, complete testing equipment and a positive service attitude, REheatek has the ability to provide stable and efficient heating solutions and products for a variety of industries. From project inception, design and development, manufacturing, quality testing to completion of delivery, every aspect of the high degree of coordination to maintain effective communication with customers. Main products include: cartridge heater, tubular heater, immersion heater, band heater, strip heater, temperature sensor and so on.