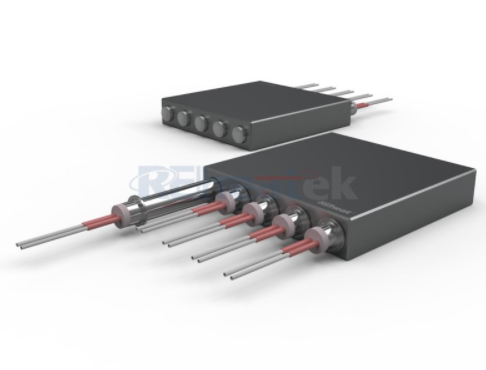

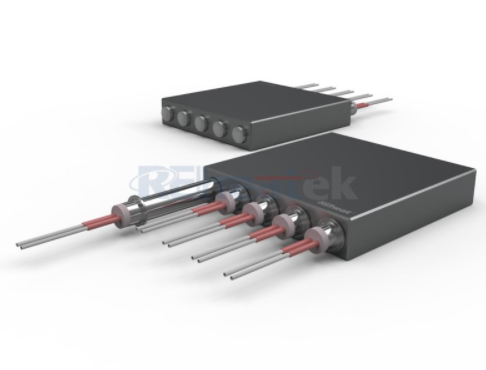

Some customers say that the cartridge heaters used in molds purchased before are easily broken and sometimes short-circuited and open-circuited. It is not as durable as many manufacturers say. what is the reason? Today, we will analyze the reasons why the cartridge heater is prone to short circuit, open circuit and rupture.

What are the reasons for the short circuit and open circuit of the cartridge heater?

1. The distance between the two holes of the lead wire is too close, resulting in a short circuit of the single-head electric heating tube.

2. The position of the heating zone of the electric heating tube is moved to the outlet and exposed to the air.

3. Excessive necessary conditions for excessive temperature and short circuit caused by the rated voltage of the two leads.

4. When in use, the aperture of the mold hole is horn-shaped, which is due to the defects in the module drilling process, which affects the heat transfer.

5. The bullet-head electric heating tube is loose at the end of the lead, which affects heat conduction and air rupture, resulting in a short circuit of the single-head electric heating tube.

6. The bottom sealing silicon is too close to the first circle of the lead root, the production process.

7. Using iron, chromium and aluminum as the excessively high resistivity of the wire to increase the temperature of the lead wire of the electric heating tube, and accidents occur.

The main reasons for the easy breakage of the cartridge heater are as follows.

1. The tightness of mold hole and mold box heater.

During the use of the cartridge heater, due to poor heating conditions and fast heat dissipation, the tube blank is often blackened, oxidized, and deformed, resulting in the internal heating element-electric heating alloy wire melting due to the combustion of high-temperature air, thus shortening the tube heater The service life of itself. Therefore, an excellent tubular heater not only requires good production quality, but also mold materials and processing holes (the closer the hole diameter is, the better). The proper aperture facilitates changing the heat between the two. Thereby extending the life of the cartridge heater itself.

2. Control of working temperature.

When the mold is used with the cartridge heater, temperature control is also crucial. Once the temperature is not controlled, the outer stainless steel tube of the cartridge heater will be blackened, oxidized, and deformed, causing the electric heating alloy wire of the internal heating element to heat up. Air burning will melt and shorten the life of the cartridge heater itself, generally controlled between 200-300°C.

3. Does the crank heater design consider the vibration of the working environment?

Before using tube heaters for mold design and production, it is also necessary to consider the vibration in the working environment. If the vibration is large, our cartridge heater will adopt a shock-proof design.

The above are the issues that we need to pay attention to when designing custom mold hole heaters to extend the service life of the cartridge heater.